Volume 11 - Year 2024 - Pages 388-396

DOI: 10.11159/jffhmt.2024.038

Feasibility Study for the Manufacturing of 3D Printing Filaments from Recycled PET: A Design of Experiments Approach

Gerardo Enrique Sosa Valenzuela1, Paola Michelle Pascua Cantarero1

pratibha.biswal@ulb.be

1Universidad Tecnológica Centroamericana (UNITEC)

Boulevard Kennedy, V-782, frente a Residencial Honduras, Tegucigalpa, Honduras

gesosav@unitec.edu;paola.pascua@unitec.edu.hn

Abstract - The research presented below aimed to determine the feasibility of recycling Polyethylene Terephthalate (PET) bottles through the manufacturing and use of 3D printing filaments at a Honduran University using Design of Experiments. Additive manufacturing has gained importance in recent years due to its advantages and innovative applications. It is used in various industries because it allows the creation of highly customized products and complex designs. One of its disadvantages is the cost of printing filaments; however, using filaments made from PET bottles could reduce associated costs. As a first step, a filament extruder was developed, and PET printing filament was manufactured through a filament extrusion process. The amount of filament that could be obtained from each size of PET bottle was then measured. Cylindrical specimens, 2.54 centimeters in diameter and 5.08 centimeters in height were 3D printed and subjected to compression strength tests in a hydraulic press to determine the material's strength. The strength of the PET-based specimens was compared with those made from Polylactic Acid (PLA). Finally, a factorial design with two factors, two levels, and ten replications was developed in Minitab, and the variance of the resistance of the specimens made from filaments of green and transparent bottles of two and three liters was analyzed. The results of the factorial design demonstrated a significant difference in the strength of the specimens manufactured from the four groups of bottles. This indicates that the color and volume of the bottle significantly affect the strength of the specimens printed with Polyethylene Terephthalate (PET).

Keywords: Strength tests, filament extrusion, 3D printing, recycling PET bottles, Design of Experiments

© Copyright 2024 Authors - This is an Open Access article published under the Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2024-04-02

Date Revised: 2024-09-24

Date Accepted: 2024-10-05

Date Published: 2024-11-04

1. Introduction

Contamination due to plastics is a problem that we encounter worldwide nowadays, various studies across different latitudes have specifically addressed plastic pollution in various water bodies, such as the study in Guatemala, which shows that one of the main contaminants on beaches is Polyethylene Terephthalate (PET) from bottles, generated by tourist, industrial, and domestic activities. [1] Another study from Ecuador shows that around 452984.556 kilograms of plastic residues were found between 2015 and 2017, the study highlights that there is less pollution in the insular region due to regulations that prohibit the use of disposable items such as PET bottles. [2] In Mexico, microplastics affect more than 700 species, from plankton to blue whales, these microplastics are produced by the mechanical action of waves and wind that fragment plastics into microparticles. [3] In Honduras, the potential applications of 3D technology have gained significant interest; its application in the industry has been explored through mathematical models [4] In addition to the aforementioned, various sustainable solutions have been analyzed at the national level. Among these initiatives, the use of robots has been implemented, which, through low-cost technologies such as 3D printing and specific mechanisms, capture floating microplastics in marine waters and rivers. [5] On the other hand, in Honduras, 3D printing has already been used in the biomedical field for various proposals related to national issues [6] In Colombia, a study determined that most of the time plastic waste enters the environment from poorly managed landfills or through careless disposal practices. [7] To prevent the plastic residues produced at the local University, an investigation on the feasibility of manufacturing and utilizing recycled PET 3D printing filaments will be conducted. To determine the feasibility, the 3D filament will be manufactured from PET bottles, the filament obtained will be measured, cylindrical specimens will be printed and subjected to compression strength to determine the load resisted, and finally, an Analysis of Variance (ANOVA) will be conducted to determine if there exists a significance difference in strength from the different PET bottles. In Mexico a study regarding recycling through filament extrusion was conducted, the study shares that 11% of residues are polymers and that only 15% of polymeric residues are recycled. Through Design of Experiments the filament properties were measured and compared. [8]

Based on all the above, the general objective of this study was to evaluate the feasibility of the Universidad Tecnológica Centroamericana (Unitec) to produce and use its own filament made from PET bottles by applying Design of Experiments

2. Methodology

2.1. Research Approach

A quantitative approach was chosen due to the engineering nature of the research tools utilized. Design of Experiments, incorporating statistical analysis techniques like sampling, descriptive statistics, and Analysis of Variance (ANOVA), was employed to quantify changes in objects. The quantitative approach as a structured process used sequentially to test hypotheses. It is suitable for estimating magnitudes or occurrences of phenomena and aims for objectivity, predictability, and generalizability of findings. This approach is characterized by its structured nature, aiming to describe, explain, and predict investigated phenomena. [9]

2.2. Research Scope

This study utilized an experimental research design, as described in "Metodologías de investigación educativa". Experimental research involves subjecting objects or individuals to specific conditions while observing their reactions. Researchers manipulate one or more variables of interest to control their effects on observed behaviors, resulting in highly specific findings. This approach grants researchers control over variables to attain desired outcomes. [10]

2.3. Variables

- Extrusion temperature: The optimal temperature to minimize crystallization during the manufacturing.

- Extrusion speed: The ideal speed to minimize crystallization during the production of PET filament.

- Amount of filament extracted: Meters of filament extracted from each Polyethylene Terephthalate (PET) bottle.

- Material compression resistance: kilograms (kg) of load supported by each specimen in the hydraulic press.

2.4. Population and Sample

2.4.1. Population

- Population 1: Ten 2L bottles collected over two days.

- Population 2: Seven 3L bottles collected over two days.

The population consisted of the quantity of Polyethylene Terephthalate (PET) bottles (plastic waste) produced over two days by the bottle collector. The bottle collector receives 14.74 kilograms of PET waste per month, approximately 0.49 kilograms daily.

2.4.2. Sampling Method

For this research, a simple random sampling method was employed. This choice is based on the assurance that all individuals within the population have an equal opportunity or probability of being included in the sample. [11]

2.4.3. Sample

With a confidence level of 95%, a probability of 50%, and a margin of error of 5%, the samples are as follows:

- Sample 1: two-liter bottles

- Sample 2: three-liter bottles

=6.89 = 7 three-liter bottles

=6.89 = 7 three-liter bottles2.4.4 Validation Methodology

This project was validated through piloting, which involved conducting a smaller-scale study to analyze the effectiveness of the methodologies and procedures used for measurement throughout the study. Piloting is essential as it reduces errors that can affect our measurements and results. Failing to conduct pilot tests can impact the validity and credibility of our study. In this research, pilot tests were carried out for filament extrusion, measurement of the amount of filament obtained from each bottle, and finally for mechanical tests on the hydraulic press.

The second validation methodology used for this research was validation with two experts in the field of Design of Experiments. This type of validation is very important to gain different perspectives and enhance the understanding of the information. It was validated that the two-factor factorial design was appropriate, captured the variation, that the variables were relevant, and that it met the equality of variances tests.

The third and final validation methodology employed was the normality test of the residuals. This validation methodology involved calculating the residuals and subsequently obtaining a normality plot of the residuals. The validity of the factorial design model was determined as the residuals were normally distributed. This helps us know that the model is reliable and that the information to be analyzed is relevant.

2.4.5 Techniques and instruments applied

Instruments

- Measuring tape: Instrument used to measure the amount of filament obtained from each bottle.

- Hydraulic press: Instrument used to determine the resistance of the test specimens under compression.

Techniques

- Microsoft Excel (MS Excel): Software used to record the data obtained from the material resistance tests.

- Minitab: Software used to perform the statistical analysis of the resistances and the amount of filament obtained from each type of bottle.

- Descriptive statistics: Technique used to calculate the maximum and minimum length of the filaments obtained from Polyethylene Terephthalate (PET) bottles

3. Analysis and Results

3.1. Measurement of the Amount of Filament Obtained from Two- and Three-Liter Bottles

3.1.1. Pilot Testing for 3D Printing Filament Manufacturing

The pilot test established optimal settings of 18 RPM and temperatures ranging from 185°C to 205°C for filament production. These settings yielded ideal filament texture, crystallization, and clarity, crucial for high-quality 3D printing. Crystallization directly influences filament mechanical properties and print quality. Validation by polymer experts from a local recycling facility confirmed the accuracy of the obtained data.

3.1.2. Pilot Testing for 3D Printing Filament Length Measurement

The results of the pilot test are as follows:

- Measuring filament with two individuals is crucial to minimize errors caused by coiling. This approach enhances accuracy by mitigating the impact of filament knots.

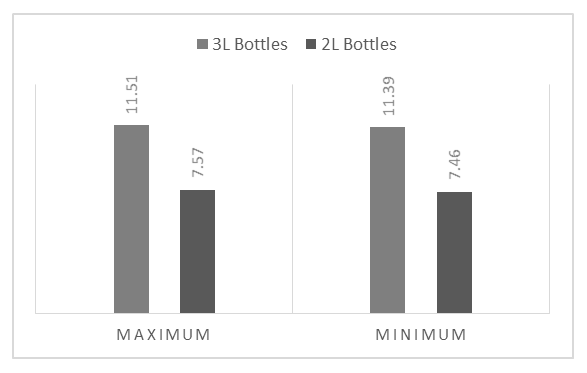

- The three-liter bottle yielded the highest amount of filament among the two types tested, averaging 11.49 meters. From the two-liter bottle, an average of 7.52 meters of filament was obtained.

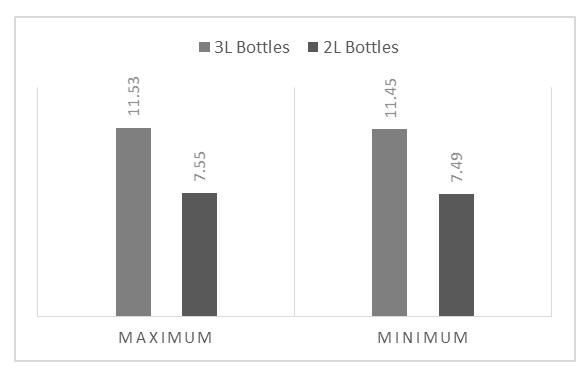

- Filament length depends on the pressure applied during bottle cutting. Higher pressure produces thicker strips, whereas less pressure yields thinner ones. Moderate pressure is ideal for achieving optimal cutting results. The graph of max and min results is shown in Figure 1.

3.1.3. Measurement of The Amount of Filament Obtained from Two- and Three-Liter Bottles

To assess the yield of Polyethylene Terephthalate (PET) filament from two and three-liter bottles, filament measurements post-manufacturing were conducted. Descriptive statistics analysis revealed maximum and minimum values, shown in Figure 2, providing insights into filament length variability.

- The three-liter bottle yields more filament, averaging 11.44 meters, compared to 7.52 meters from the two-liter bottle.

- Variation in filament length is due to the bottle-cutting process. Pressure is applied while rotating the bottle against the blade to convert it into strips, resulting in varying strip thicknesses and filament lengths.

3.2Measurement of The Resistance to compression of Polyethylene Terephthalate (PET) and Poly-Lactic Acid (PLA) Specimens

3.2.1. Pilot Testing for Specimen Fabrication

The test specimen size for use with the hydraulic press was determined in collaboration with Engineer Juan Carlos Reyes. Four specimens made from PLA and three specimens made from PET bottles were printed, each with a height of 5.08 cm and a diameter of 2.54 cm. The objective of this pilot test was to establish the conditions under which this filament should be printed.

It was determined that the best configuration for this filament is the ULTRAFUSE PET profile, with an extrusion temperature of 250°C and a bed temperature of 80°C. This configuration was used with the PRUSA i3 MK3S+ printer. The Pilot Printing is shown in Figure 3 below.

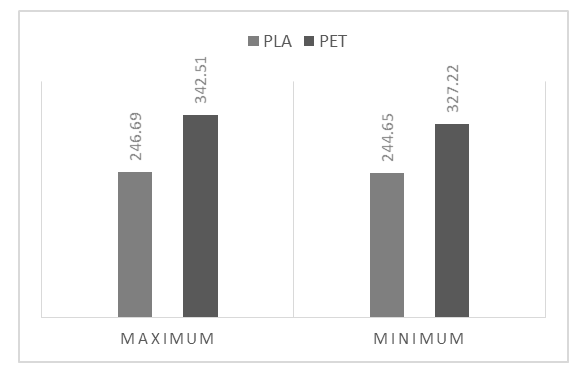

3.2.2. Pilot Testing of Resistance Measurement with Hydraulic Press

As a result of the pilot test, it was determined that the test specimens and the press configuration were suitable for the official testing of the sample. The maximum load supported by the specimens printed with red Polylactic Acid (PLA) is lower than the load supported by the specimens printed with Polyethylene Terephthalate (PET). On average, PLA supported approximately 245.67 kilograms, while PET supported approximately 335.03 kilograms, demonstrating a difference of approximately 89.36 kilograms. The upper and lower limits of the results of the pilot test are shown in Figure 4 below.

3.2.3. Resistance of Poly-Lactic Acid (PLA) versus Polyethylene Terephthalate (PET) Specimens

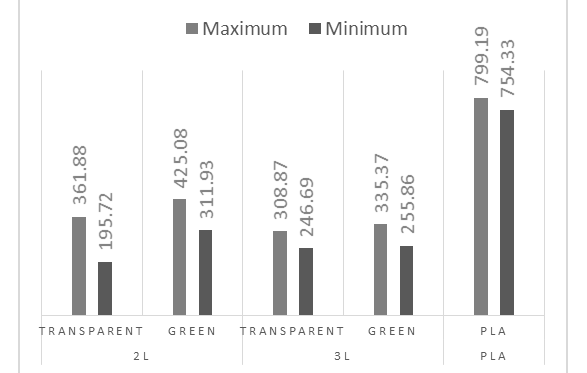

To evaluate the compressive strength of PLA and PET specimens, ten samples of each material were prepared, totaling 50 specimens. Each specimen underwent compression testing using a hydraulic press to determine its maximum load capacity. The variable measured was the specimens' compressive strength in kilograms. Figure 6 illustrates the upper and lower limits of the load borne by the specimens.

The results obtained from this test are as follows:

- PET filament specimens from two-liter bottles demonstrate greater compressive strength than those from three-liter bottles, attributed to the thicker walls of the two-liter bottles. On average, transparent filament specimens from two-liter bottles exhibit 10 kilograms higher resistance than those from three-liter bottles. Similarly, filament from two-liter green bottles shows 61.85 kilograms higher compressive strength compared to three-liter bottles.

- Specimens printed with 3D printing PET filament from green bottles exhibit higher resistance compared to those from transparent bottles. On average, filament from two-liter green bottles withstands 66.83 kilograms more than filament from two-liter transparent bottles. Similarly, green filament specimens from three-liter bottles endure 15.05 kilograms more than transparent ones on average.

- PLA specimens were more resistant than those made from PET. Variation in PLA resistance between pilot tests and samples was due to PLA characteristics during printing. PET specimens' compressive strength falls within the range shown by the least and most resistant PLA samples.

3.3. Variability in the Compressive Strength of Specimens Fabricated with PET Filament from Green and Transparent Bottles of Two and Three Liters, and Material Stability

3.3.1. Analysis of Variance for the Compressive Strength of Specimens Printed with Filament from Bottles of Different Colors and Volumes

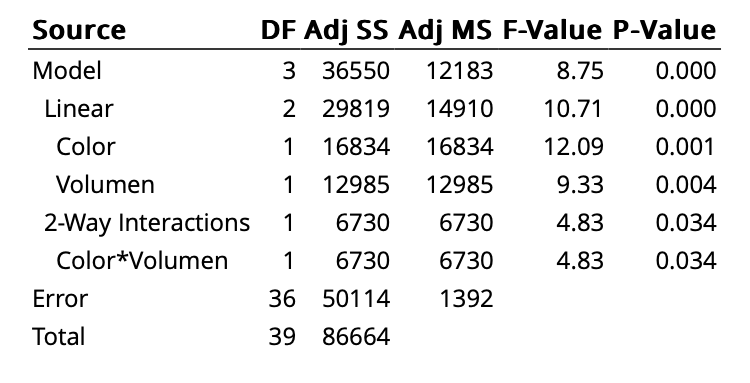

The Analysis of Variance (ANOVA) for the compressive strength of specimens fabricated with 3D printing filament from green and transparent Polyethylene Terephthalate (PET) bottles of two and three liters aimed to determine if there is a significant difference in the means of the printed specimens' strength. A two-factor, two-level factorial design with ten replications was formulated, where the null hypothesis assumed equal means (H:

As a result of the Analysis of Variance (ANOVA) for the compressive strength of specimens printed from green and transparent bottles of two and three liters, the following outcomes were obtained:

- The overall model is statistically significant, evidenced by an F-value of 8.75 and a P-value of 0.000 < 0.05 in Table 1. This indicates that at least one factor or their interactions significantly affect the response variable. [13]

- The analysis of the 40 specimens indicates significant effects of the color factor (P-value = 0.001) and the volume factor (P-value = 0.004) on the response variable (Strength). These factors contribute to the observed variability in the compressive strength test data obtained from the hydraulic press.

- The interaction between color and volume is significant (P-value = 0.034), suggesting that the effect of one factor may depend on the level of the other. This significant interaction between color and volume affects the response variable (Strength).

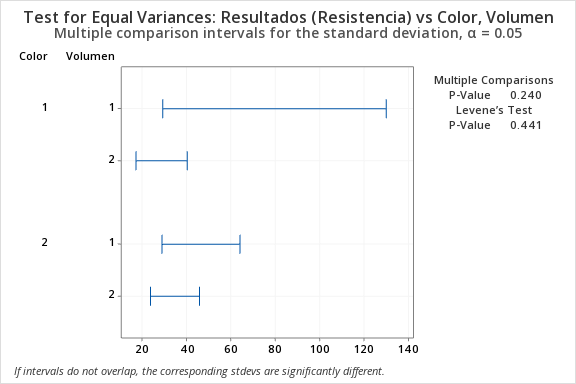

3.3.2. Test of Equal Variances, Residuals vs Color and Volume

The purpose of the residual variance equality test was to determine whether the variances of the residuals or residual errors remain constant across levels of the independent variable in the factorial design model. This test aims to ascertain whether there is sufficient evidence to reject the null hypothesis that the variances are equal (![]() ). [14] The equal variances test graph can be seen below in Figure 6.

). [14] The equal variances test graph can be seen below in Figure 6.

As a result of the residual variance equality test, it was determined that the variances remain constant with a 95% Confidence Level. In Levene's test, a p-value of 0.441 was obtained, which is greater than the significance level α = 0.05, indicating acceptance of the null hypothesis and thus non-rejection. [15] The variances of the residuals among the four groups (green two-liter bottles, transparent two-liter bottles, green three-liter bottles, and transparent three-liter bottles) are statistically equal. This validation of assumptions contributes to the determination of reliable results.

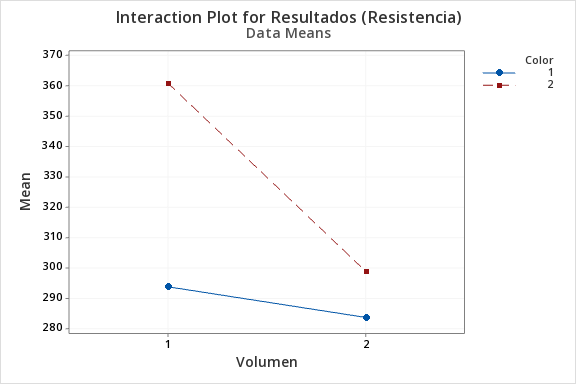

3.3.3. Interaction of Factors and Response Variable

An interaction plot was created to visualize and analyze the interaction between variables, aiding in understanding their effects on the experiment's outcomes. Generated using Minitab, it depicts how color and volume factors interact and influence the response variable (Resistance). This plot, shown in Figure 7, provides insights into the relationship between color, volume, and resistance.

The results of the interaction test for the outcomes are as follows:

- There is a significant difference in the means of resistance among the four groups. Color and volume have a significant effect on the response variable (resistance).

- The factor with the greatest influence on resistance is the color of the bottle, followed by volume, and the interaction between color and volume. This can be observed in the difference in the slopes of the lines in Figure 5.

3.4. Description of validation methods

3.4.1. Pilot Testing Validation

Pilot testing validated: the ideal extrusion temperature and speed, the measurement of the 3D filament length, the ideal extrusion and bed temperature for 3D printing, and the compression strength test measurements.

3.4.2. Expert Validation

As a result of the validation with experts, the following was obtained:

- The measurement instruments are suitable for accurately measuring filament quantity from two- and three-liter bottles, as well as for assessing the compression resistance of specimens. This ensures the validity of measurement results.

- The sample size chosen for the study is appropriate, providing sufficient data for interpretation using statistical analysis with Minitab.

- The employed two-factor, two-level, and ten-replication factorial design is valid. Significant factors such as color, volume, and their interaction have been appropriately utilized, with the model showing significance at a confidence level of 95%. This indicates that color, volume, and their interaction significantly influence the resistance of printed specimens.

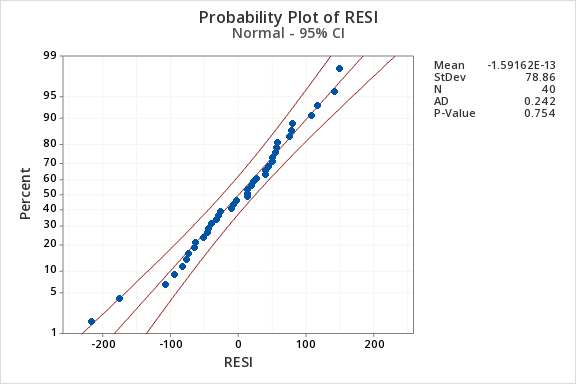

3.4.3. Model Validation with Residual Normality Test

As a result of the normality test, a p-value of 0.754 was obtained, which is greater than 0.05, suggesting that the residuals follow a normal distribution. [16] The model adequately captures the variability in the data, and there are no systematic biases in the predictions. The model is valid, and the conclusions derived from the model are reliable with a 95% Confidence Level. The model serves as a useful tool for understanding the relationship between the predictor variables and the response variable in the study. The normality test graph can be seen below in Figure 8.

4. Costs Associated with Filament Production

4.1. Water Costs

One cup of water was used per bottle in the production of filament to eliminate residues from the beverages. The cost of cleaning each bottle is $0.000192, if the water consumption ranges from 21 to 60 cubic meters, with a cost of $0.768 per cubic meter. The equivalent cost for producing 1 kg of filament is $0.00336, which corresponds to the amount found in traditional filament rolls.

4.2. Electricity Costs

The energy consumption per hour is 0.462 kWh, equivalent to $0.102, assuming the price per kWh is $0.221992. To produce 1 kg of filament, a cost of $2.1024 is incurred. This involves using 7 bottles of 3L, which take 1.5 hours to convert to filament, and 10 bottles of 2L, which take 1 hour.

4.3. Labor Costs

The daily labor cost is $20. During a 9-hour workday, 67 bottles can be processed, as each bottle takes approximately 7 to 8 minutes to cut. To produce 1 kg of filament using 7 bottles of 3L and 10 bottles of 2L, the labor cost amounts to $5.036, assuming each bottle takes 8 minutes to cut.

These cost calculations are based on production in Honduras, where local prices for water, electricity, and labor can significantly impact the overall cost of filament production. Understanding these regional factors is crucial for accurately assessing production expenses.

Table 2: Cost Breakdown per Kilogram of Filament.

|

Cost Component |

Amount ($) |

|

Water |

0.00336 |

|

Electricity |

2.1024 |

|

Labor |

5.036 |

|

Total |

7.44 |

5. Discussion

The filament length measurements show that three-liter PET bottles yield more filament than two-liter ones, averaging 3.93 meters longer. Differences attributed to bottle cutting and shape. Green PET requires approximately 5°C higher extrusion temperature than transparent PET, resulting in greater filament elongation. In this case the ideal extrusion temperature for this material, measured with the sensor of the ORIGINAL PRUSA i3 MK3S+ printer, is 250°C. This temperature provided the optimal fluidity of the filament and ensured that the printed design maintained its translucency. Additionally, it was found that the ideal bed temperature is 80°C, which prevented the printed objects from detaching from the printer bed.

The Mechanical compression tests on hydraulic press-printed specimens showed that PET filament specimens exhibited higher resistance than less resistant PLA filament specimens, with an average of 89.18 kilograms more than PLA. Compared to stronger PLA filament, PET specimens were weaker, with an average of 464.45 kilograms less resistance. Two-liter bottle filament specimens resisted 41.54 kilograms more than three-liter bottle filament specimens due to thicker bottle walls. Moreover, in both cases, green filament specimens resisted higher loads than transparent filament specimens, attributed to the curing process of green PET.

The ANOVA analysis shows that the model with a p-value of 0.000 < 0.05 is highly significant. Notably, Color and Volume factors individually exhibited significant effects, with respective p-values of 0.001 and 0.004, suggesting measurable and statistically significant impacts on resistance. Additionally, color-volume interaction was significant, with a p-value of 0.034. The factorial design model is highly significant, indicating significant effects of factors and their interaction on resistance. However, predictive and generalization capabilities could be improved with additional adjustments. The model explains at least 42.17% of data variability, with a predictive determination coefficient of 28.61%, suggesting the model's limited effectiveness in predicting new data. Also, the residual variance equality test, with a p-value of 0.441 and α=0.05, indicates constant variances across different color and volume levels. The difference between observed and predicted values by the factorial design doesn't significantly vary based on color and volume. The study's model adequately explains the relationship between color, volume, and resistance.

6. Conclusions

The manufacturing and use of 3D printing filament made from polyethylene terephthalate (PET) bottles at the Honduran University is viable. The collection of raw materials (bottles) can be conducted on-site, promoting recycling among students, faculty, administrative staff, and support personnel. Both the manufacturing and printing of objects can be carried out seamlessly.

The cost of producing 1 kg of filament is approximately $7.44, which is $28.56 cheaper than a traditional filament roll priced at approximately $36.00. In terms of strength, the filament ranks between the less resistant variant of polylactic acid (PLA), and more resistant variant, making it suitable for printing objects that do not need to withstand loads greater than 309.45kg, based on the average strength of the 40 printed samples.

The interaction plot demonstrated that to maximize print strength, filament made from two-liter green PET bottles should be used, as it exhibits the highest response variable value (resistance). The validation through pilot testing, expert validation, and residual normality testing demonstrated the validity of the two-factor, two-level, ten-replicate factorial design. The factorial analysis results and conclusions derived from the study can be trusted.

As future work is necessary to improve the production process through Operations Improvement Systems, aiming to enhance the manufacturing process of 3D printing filament made from Polyethylene Terephthalate (PET) bottles. The implementation of techniques such as Single Minute Exchange of Dies (SMED) could help reduce manufacturing times, decrease changeover times for producing green or clear filament, and improve filament quality, which would enhance the strength of the final print. Conducting an Overall Equipment Effectiveness (OEE) analysis will help determine the effectiveness of the filament extruder and identify opportunities for improvement.

7. Acknowledgements

We sincerely thank Leonel Molina, Ismael Abarca, Favell Núñez, and Juan Carlos Reyes for their support and contributions throughout the development of this work. Their involvement and encouragement were greatly appreciated.

References

[1] C. Mazariegos-Ortíz, L. García-Arroyave, C. Marroquín-Mora, y A. L. Mendizábal, “Contaminación por microplásticos en playas del Pacífico de Guatemala: abundancia y características”, Cienc. Tecnol. Salud, vol. 8, núm. 2, pp. 260–268, dic. 2021, doi: 10.36829/63CTS.v8i2.904. View Article

[2] J. López-Aguirre, J. Pomaquero-Yuquilema, y J. López-Salazar, "Análisis de la contaminación ambiental por plásticos en la ciudad de Riobamba", Pol. Con., vol. 5, núm. 12, p. 19, dic. 2020, doi: 10.23857/pc.v5i12.2139.

[3] M. Rivas y O. Garelli, "Impacto de la contaminación por plásticos en la biodiversidad y patrimonio biocultural de México", mar. 2021, [En línea]. Disponible en: https://mx.boell.org/es/2021/03/10/impacto-de-la-contaminacion-por-plasticos-en-la-biodiversidad-y-patrimonio-biocultural

J. L. Ordoñez Avila, M. E. Perdomo, M. Y. Rivas Bejarano, and J. L. Ordoñez Fernández, "Mechanical Displacement for 3D Printers’ Parts Using FEM as Inverse Engineering Method in Honduras," Journal of Physics: Conference Series, vol. 1877, no. 1, 2021, doi: 10.1088/1742-6596/1877/1/012013 View Article

J. L. Ordoñez-Avila, S. J. Lazaro-Cardenas, and R. Espinal Lanza, "3D Printed Structures for Under Water Robots Design," in Proceedings of the 9th World Congress on Mechanical, Chemical, and Material Engineering (MCM'23), Brunel University, London, United Kingdom, Aug. 06-08, 2023, Paper No. ICMIE 137, DOI: 10.11159/icmie23.137, pp. ICMIE 137-1 View Article

[6] Coello, C., Rodríguez, M., & Zambrano Amador, S. G. (2023). Integration of image processing and 3D printing for enhanced intracranial malformation detection and surgical planning. In F. Cáceres Lagos (Faculty Mentor), Proceedings of the LACCEI 2023 Conference (Digital Object Identifier: 10.18687/LACCEI2024.1.1.1974). Universidad Tecnológica Centroamericana UNITEC, Honduras. View Article

[7] R. Sarria-Villa y J. Gallo-Corredor, "La gran problemática ambiental de los residuos plásticos: Microplásticos", Journal de Ciencia e Ingeniería, vol. 8, núm. 1, p. 7, ago. 2016.

[8] M. Hernández, "Diseño de Experimentos Para el Reciclaje de Polietilento a Través de la extrusión de Filamentos", Universidad Panamericana, Ciudad de México, 2019. Consultado: el 28 de enero de 2024. [En línea]. Disponible en: http://biblio.upmx.mx/tesis/198939.pdf

[9] R. Hernández Sampieri y C. P. Mendoza Torres, Metodología de la investigación: las rutas cuantitativa, cualitativa y mixta, First edition. México: McGraw-Hill Education, 2018.

[10] G. P. Guevara Alban, A. E. Verdesoto Arguello, y N. E. Castro Molina, "Metodologías de investigación educativa (descriptivas, experimentales, participativas, y de investigación-acción)", pp. 163–173, jul. 2020, doi: 10.26820/recimundo/4.(3).julio.2020.163-173. View Article

[11] T. Otzen y C. Manterola, "Técnicas de Muestreo Sobre una Población a Estudio", Int. J. Morphol, p. 6, 2017. View Article

[12] H.-Y. Kim, “Analysis of variance (ANOVA) comparing means of more than two groups”, Restor. Dent. Endod., vol. 39, núm. 1, p. 74, 2014, doi: 10.5395/rde.2014.39.1.74. View Article

[13] H. Gutiérrez Pulido y R. de la Vara Salazar, Análisis y diseño de experimentos, 2a ed. México: McGraw-Hill, 2008.

[14] J. L. Gastwirth, Y. R. Gel, y W. Miao, “The Impact of Levene’s Test of Equality of Variances on Statistical Theory and Practice”, Stat. Sci., vol. 24, núm. 3, ago. 2009, doi: 10.1214/09-STS301. View Article

[15] M. E. O’Neill y K. L. Mathews, “Levene Tests of Homogeneity of Variance for General Block and Treatment Designs”, Biometrics, vol. 58, núm. 1, pp. 216–224, mar. 2002, doi: 10.1111/j.0006-341X.2002.00216.x. View Article

[16] A. F. Schmidt y C. Finan, “Linear regression and the normality assumption”, J. Clin. Epidemiol., vol. 98, pp. 146–151, jun. 2018, doi: 10.1016/j.jclinepi.2017.12.006. View Article

[1] C. Mazariegos-Ortíz, L. García-Arroyave, C. Marroquín-Mora, y A. L. Mendizábal, “Contaminación por microplásticos en playas del Pacífico de Guatemala: abundancia y características”, Cienc. Tecnol. Salud, vol. 8, núm. 2, pp. 260–268, dic. 2021, doi: 10.36829/63CTS.v8i2.904. View Article

[2] J. López-Aguirre, J. Pomaquero-Yuquilema, y J. López-Salazar, "Análisis de la contaminación ambiental por plásticos en la ciudad de Riobamba", Pol. Con., vol. 5, núm. 12, p. 19, dic. 2020, doi: 10.23857/pc.v5i12.2139.

[3] M. Rivas y O. Garelli, "Impacto de la contaminación por plásticos en la biodiversidad y patrimonio biocultural de México", mar. 2021, [En línea]. Disponible en: https://mx.boell.org/es/2021/03/10/impacto-de-la-contaminacion-por-plasticos-en-la-biodiversidad-y-patrimonio-biocultural

J. L. Ordoñez Avila, M. E. Perdomo, M. Y. Rivas Bejarano, and J. L. Ordoñez Fernández, "Mechanical Displacement for 3D Printers’ Parts Using FEM as Inverse Engineering Method in Honduras," Journal of Physics: Conference Series, vol. 1877, no. 1, 2021, doi: 10.1088/1742-6596/1877/1/012013 View Article

J. L. Ordoñez-Avila, S. J. Lazaro-Cardenas, and R. Espinal Lanza, "3D Printed Structures for Under Water Robots Design," in Proceedings of the 9th World Congress on Mechanical, Chemical, and Material Engineering (MCM'23), Brunel University, London, United Kingdom, Aug. 06-08, 2023, Paper No. ICMIE 137, DOI: 10.11159/icmie23.137, pp. ICMIE 137-1 View Article

[6] Coello, C., Rodríguez, M., & Zambrano Amador, S. G. (2023). Integration of image processing and 3D printing for enhanced intracranial malformation detection and surgical planning. In F. Cáceres Lagos (Faculty Mentor), Proceedings of the LACCEI 2023 Conference (Digital Object Identifier: 10.18687/LACCEI2024.1.1.1974). Universidad Tecnológica Centroamericana UNITEC, Honduras. View Article

[7] R. Sarria-Villa y J. Gallo-Corredor, "La gran problemática ambiental de los residuos plásticos: Microplásticos", Journal de Ciencia e Ingeniería, vol. 8, núm. 1, p. 7, ago. 2016.

[8] M. Hernández, "Diseño de Experimentos Para el Reciclaje de Polietilento a Través de la extrusión de Filamentos", Universidad Panamericana, Ciudad de México, 2019. Consultado: el 28 de enero de 2024. [En línea]. Disponible en: http://biblio.upmx.mx/tesis/198939.pdf

[9] R. Hernández Sampieri y C. P. Mendoza Torres, Metodología de la investigación: las rutas cuantitativa, cualitativa y mixta, First edition. México: McGraw-Hill Education, 2018.

[10] G. P. Guevara Alban, A. E. Verdesoto Arguello, y N. E. Castro Molina, "Metodologías de investigación educativa (descriptivas, experimentales, participativas, y de investigación-acción)", pp. 163–173, jul. 2020, doi: 10.26820/recimundo/4.(3).julio.2020.163-173. View Article

[11] T. Otzen y C. Manterola, "Técnicas de Muestreo Sobre una Población a Estudio", Int. J. Morphol, p. 6, 2017. View Article

[12] H.-Y. Kim, “Analysis of variance (ANOVA) comparing means of more than two groups”, Restor. Dent. Endod., vol. 39, núm. 1, p. 74, 2014, doi: 10.5395/rde.2014.39.1.74. View Article

[13] H. Gutiérrez Pulido y R. de la Vara Salazar, Análisis y diseño de experimentos, 2a ed. México: McGraw-Hill, 2008.

[14] J. L. Gastwirth, Y. R. Gel, y W. Miao, “The Impact of Levene’s Test of Equality of Variances on Statistical Theory and Practice”, Stat. Sci., vol. 24, núm. 3, ago. 2009, doi: 10.1214/09-STS301. View Article

[15] M. E. O’Neill y K. L. Mathews, “Levene Tests of Homogeneity of Variance for General Block and Treatment Designs”, Biometrics, vol. 58, núm. 1, pp. 216–224, mar. 2002, doi: 10.1111/j.0006-341X.2002.00216.x. View Article

[16] A. F. Schmidt y C. Finan, “Linear regression and the normality assumption”, J. Clin. Epidemiol., vol. 98, pp. 146–151, jun. 2018, doi: 10.1016/j.jclinepi.2017.12.006. View Article