Volume 12 - Year 2025 - Pages 490-498

DOI: 10.11159/jffhmt.2025.049

Performance Assessment of CO2-Hydrocarbon Zeotropic Refrigerant Mixture for High-Temperature Heat Pumps

Kalkidan Mekonnen Mesheshaa, David Newporta, Gómez-Hernández, J.b, Alan Odonovana, Ronan Grimesa

aBernal Institute, School of Engineering, University of Limerick, V94 T9PX, Limerick, Ireland.

bDepartment of Thermal and Fluid Engineering, Carlos III University of Madrid, Avenida de la Universidad 30, 28911, Leganés, Spain

Meshesha.kalkidan@ul.ie

Abstract - The increasing need for energy-efficient and sustainable high-temperature heat pump systems (HTHPs) has led to extensive research into working fluids with optimal thermodynamic performance. Among various refrigerants, carbon dioxide is a promising candidate due to its favourable effects on the environment, good thermophysical properties, and economic feasibility. However, its low critical temperature and high operating pressure pose significant challenges on efficiency of the system. One of the methods to explore the use of CO₂ as a refrigerant is to mix it with other hydrocarbons and form zeotropic refrigerant mixtures. Thus, the present study investigates the performance of CO₂-based zeotropic refrigerant mixtures with six hydrocarbons. Key performance indicators, including coefficient of performance (COP), sink outlet temperature, pressure ratio, and Lorenz efficiency were evaluated for the selected mixtures at different source inlet temperatures. The results indicated that at a source inlet temperature of 90°C, a CO₂/butane mixture delivers a sink outlet temperature of 147.3°C with a COP of 5.73, making it a strong candidate for temperature < 140°C. Additionally, CO₂/butane exhibits the lowest pressure ratio and highest Lorenz efficiency of 77.7% at 90°C source inlet temperature, exhibits reduced compressor workload and improving overall efficiency. For high-temperature applications exceeding 150°C, CO₂/acetone emerges as the most suitable mixture. At the maximum source inlet temperature, it achieves a sink outlet temperature of 188.76°C with a highest COP of 6.41 among all tested mixtures. Those findings highlight the potential of CO₂-based zeotropic mixtures to enhance HTHPs performance by reducing exergy destruction and improving heat exchanger thermal matching without the need for complex system modifications.

Keywords: Temperature glide, Hydrocarbons, Lorenz efficiency, zeotropic mixture, heat pump.

© Copyright 2025 Authors - This is an Open Access article published under the Creative Commons Attribution License terms Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2025-04-10

Date Revised: 2025-10-02

Date Accepted: 2025-12-10

Date Published: 2025-12-24

1. Introduction

The growing demand for energy-efficient and sustainable heating solutions has driven extensive research into HTHPs. These systems play a critical role in industrial applications such as food processing, chemical production, and district heating. Among various working fluids, CO₂ has gained attention due to its excellent thermophysical and transport properties, non-toxic, non-flammable, readily available, as well as zero ozone depletion potential (ODP) and limited Global Warming Potential(GWP) [1]. Additionally, CO2 has several advantages over other refrigerants, such as compatibility with normal lubricants and common machine construction materials, low compression ratio, high volumetric heating capacity [2]. Moreover, the cost of CO₂ refrigerant per unit mass is around three times cheaper than that of HFC blends (R404A and R407A) [3].

Despite those advantages, it is challenging to use CO₂ as a refrigerant, primarily due to its low critical temperature (31.1 °C) and high critical pressure (7.38 MPa), which result in high operating pressure and significant performance reduction [4]. This low critical temperature leads to trans-critical conditions on the high-pressure side of the cycle in many applications [5]. The trans critical CO2 driven HPs have been shown to have high irreversibility caused by throttling losses and superheated vapor horns, which results in low COP [6]. Under trans-critical conditions, condensation heat transfer does not occur at a constant temperature. Thus, the pressure is not determined by the constant condensing temperature, as it varies and can also be optimized. This high optimal pressure results in substantial losses at the throttle valve, which reduces the overall efficiency of the system [5]. To address these issues, many advanced technologies have been introduced, like ejectors, parallel compression, two stage compression, mechanical sub cooling, dedicated mechanical sub cooling. However, the introduction of improved technology requires additional equipment to modify the system configuration which increases the initial capital cost and makes the system configuration more complex. To enhance the system energy efficiency without adding additional equipment, mixing CO2 with other refrigerants to form zeotropic refrigerant mixture is one of the solutions to achieve a higher critical point Temperature and lower working pressures [7]. This method extends the subcritical operation of pure CO2, minimizing the compressor work and the high throttling losses. Moreover, the zeotropic temperature glide effect allows a better matching between the refrigerant and the secondary fluid and hence reduces the irreversibility during the heat exchange process.

Several researchers have shown the importance of CO₂-based zeotropic mixtures to significantly enhance the performance and efficiency of heat pump systems. Sarkar and Bhattacharyya [8] explored CO₂/R600 and CO₂/R600a (0.5/0.5) mixtures for medium and high-temperature heat pumps, The result indicates that refrigerant mixtures of CO₂/ R600a have more than twice the COP than that of R600. R600a mixtures also enable the elimination of the extremely high-pressure requirements of CO₂ systems, making it the best alternative working fluid for CO₂ heating.

Toffoletti et al., [9] evaluated CO₂/( R-290,R-600a, and R-600) blends and demonstrated that the addition of hydrocarbons significantly increases the critical temperature while lowering system pressure, allowing more efficient operation in the near-critical region.

Li et al., [10] investigated a trans-critical CO₂-based mixture heat pump for simultaneous heat and cold energy recovery, achieving exergy efficiencies up to 60%.

Ju et al.,[11] also tested CO₂-propane mixtures for high sink temperature lift, identifying an optimal mass fraction of 12%/88%. This mixture was proposed as an alternative to R22, showing increased COP and better heating capacity. Koyama et al., [12] on the other hand, tested a mixture of CO₂ with 10% dimethyl ether (DME) and found no significant differences in COP but a notable reduction in optimal discharge pressure by 2 MPa and 1.9 MPa for heating and cooling mode, respectively. A recent study by Gomez et al., [13] showed that a mixture of 5% CO₂ and 95% Acetone achieves a COP of 5.66 for industry scale HTHPs at the target sink outlet temperature of 200 °C. Onaka et al., [14] also investigated the evaporation heat transfer of CO₂/DME mixtures in a horizontal tube and observed a reduction in the heat transfer coefficient by 20% for a 10% CO₂ mixture and by 48% for a 25% CO₂ mixture. Ren et al., [15] studied the flow boiling characteristics of a zeotropic R290/R601a mixture in a mini-channel, demonstrating that composition, mass flux, and vapor quality strongly influence local heat-transfer coefficients and pressure drops.

Thus, the present study investigates the performance of blends of CO₂ with six different hydrocarbons namely butane, pentane, isopentane, diethyl ether (DEE), methanol, and acetone for HTHPs. The performance of HTHPs is significantly influenced by the thermodynamic properties of the working fluid. These proposed zeotropic refrigerant mixtures, characterized by temperature glide during phase change, can offer improved thermal performance by better matching the temperature profiles of heat exchangers. This approach can lead to increased COP, reduced exergy destruction, and increased overall system efficiency.

2. Methods

This section presents the heat pump layout and assumptions used for modelling the HTHPs, along with performance analysis of the working fluid. In the present study DW-Therm HT (heat transfer fluid) is used as a heat source with inlet temperature range 50-130 ℃, and water is used as a heat sink. The source inlet temperature was the main input parameter for the entire system at constant lift temperature that influences the system’s performance. REFPROP software version 10.1 [16] was linked to excel to obtain properties of the working fluid and for further system analysis.

The choice of refrigerant plays a crucial role in the performance, reliability, and safety of HTHPs. Selecting the appropriate refrigerant for high-temperature operation is essential. Table 1 shows the refrigerants considered in the present study and their distinct thermophysical properties which influence suitability for HTHPs. Good miscibility of CO₂ in all six hydrocarbons is assumed. In addition, 5% of CO₂ composition with 95% of secondary hydrocarbon composition were assumed for all selected zeotropic refrigerants.

Table 1. General properties of selected refrigerants

|

Refrigerant |

General Property |

|

Carbon Dioxide |

High heat transfer coefficient, non-flammable, environmentally friendly, but operates at high pressures |

|

Butane |

Low boiling point, moderate operating pressure, and good thermodynamic efficiency. |

|

Pentane |

Higher boiling point than butane, lower vapor pressure, and favourable temperature glide characteristics. |

|

Isopentane |

Like pentane but with slightly different thermodynamic properties, useful for enhancing heat transfer. |

|

Diethyl Ether (DEE) |

Low boiling point, good heat transfer properties, but flammable. |

|

Methanol |

Low molecular weight, moderate pressure, but hygroscopic. |

|

Acetone |

High volatile, good thermal stability, but flammable. |

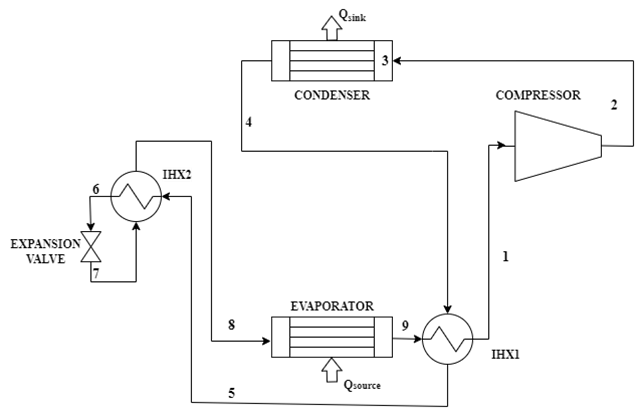

Figure 1 shows a HTHPs layout for zeotropic refrigerants, a layout similar to standard heat pump layout but with additional two internal heat exchangers, IHX1 and IHX2. IHX1 ensures dry compression. Following compression to state 2, IHX2 located before the expansion valve enable the refrigerant to be sub-cooled liquid at the entrance to the throttle valve. This reduces the formation of unwanted flash gas during expansion. The zeotropic nature of the CO₂/HC mixture necessitates the identification of state 3, which signifies the onset of condensation. Due to the temperature glide occurring during the phase change, saturated vapour is identified at state 3 within the condenser. State 4 then exchanges heat with the outlet fluid from the evaporator at state 9 before exiting IHX1 and entering IHX2. Finally, within IHX2, heat is transferred from state 6 to the low-pressure stream, transitioning it from state 7 to state 8, after which state 6 undergoes a throttling process.

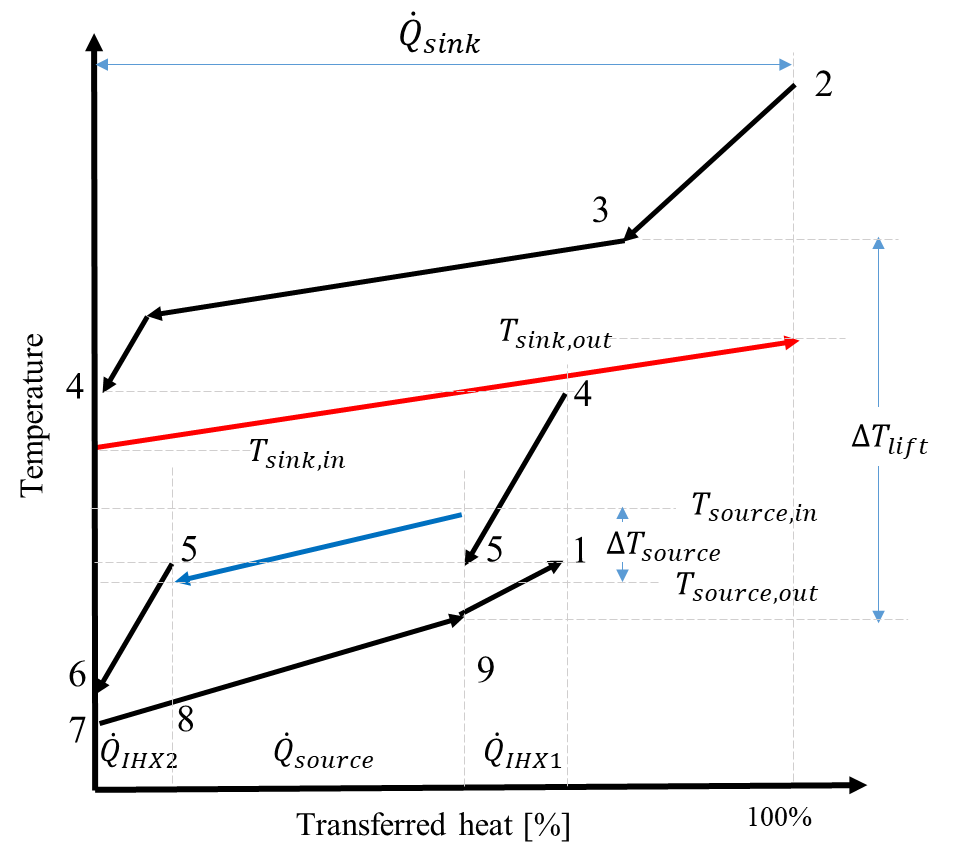

Figure 2 depicts a temperature-heat diagram for the heat pump layout, illustrating the temperature changes of both the heat source and sink as a function of transferred heat percentage. The black line represents the refrigerant mixture, the blue line represents the heat source, and the red line represents the heat sink, where the refrigerant releases heat, beginning with state point 3, and then condensation will occur in process 3-4, and finally subcooling processes 4-5 and 5-6 before returning to the evaporator. The temperature difference between the dew points of the evaporator and the condenser is denoted by ∆Tlift, which is a critical parameter influencing the heat pump's performance.

The entire system has been modelled based on the energy balance of individual components, leading to the derivation of the conservation equations. Steady-flow energy equations, in accordance with the first law of thermodynamics, have been applied to each component. The following assumptions were made for the theoretical analysis:

- The heat loss to the environment is neglected.

- The refrigerant is assumed to be saturated vapor at the outlet of the evaporator.

- The flow configuration within the heat exchangers is counterflow.

- The compressor functions with a constant isentropic efficiency (ηis) of 0.85. [17]

- The expansion valve undergoes an isenthalpic expansion process.

- ∆TIHX1=5K=T5-T9, [18]

- ∆Tsink pinch= ∆Tsource pinch= 2.5 K [19]

- Superheat at the compressor inlet (∆𝑇𝑆𝐻) = 5 K

- Source temperature difference (∆𝑇𝑠𝑜𝑢𝑟𝑐𝑒) = 10 K

2.1. Performance Analysis

The evaluation of HTHPs relies on several critical performance indicators. The sink outlet temperature is one of performance parameters which quantifies the system's ability to deliver thermal energy at high temperature levels required for specific industrial applications. COP relates the supplied heat ![]() to the consumed electric power of the compressor

to the consumed electric power of the compressor ![]() .

.

VHC and thermodynamic average temperature of condenser also serve as critical performance metrics. VHC reflects the system’s ability to deliver heat per unit volume of refrigerant flow, directly influencing system efficiency and compactness which is expressed as.

The thermodynamic average temperature of condenser in a heat pump system is defined based on the exergy-temperature relationship, given by the ratio of enthalpy change to entropy change during the condensation process [20].

Lorenz efficiency ηlorenz relates the COP to the maximum achievable COPlor for finite heat reservoirs in terms of a Lorenz cycle [21] and therefore gives an indication about the improvement potentials.

Where: Tsink,av and Tsource,av are average sink and source temperature of the HTF respectively.

3. Result and discussion

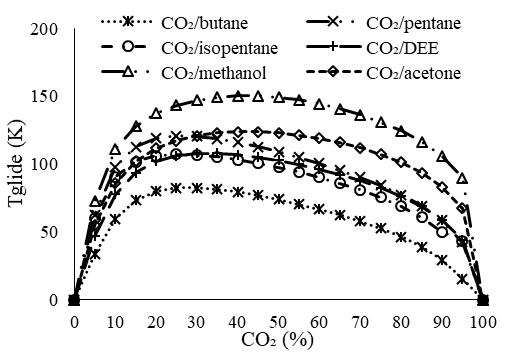

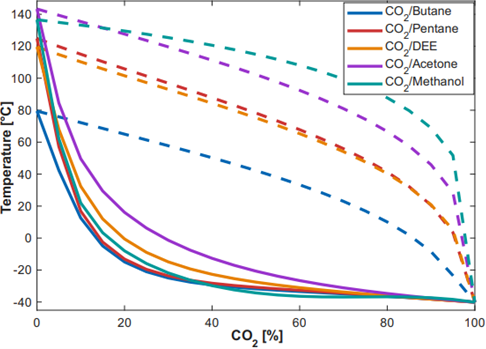

This section starts with presenting the glide temperature, bubble, and dew point temperature with respect to carbon dioxide composition of the selected mixtures. Then, the next sections present the results of the performance analysis of the HTHPs using proposed CO2 based zeotropic refrigerants. Figures 3 and 4 illustrate glide temperature, bubble and dew point temperatures variation of this proposed zeotropic mixture with composition of CO2 at pressure of 10 bar.

The result indicates that CO₂ / butane mixture has the lowest Tglide compared to all other proposed zeotropic mixtures and CO₂ /methanol have the highest glide temperature. At 10 bar, for 5% CO₂ /95% HC the glide temperatures follow the order CO₂/butane (33.47 °C) < CO₂/acetone (54.85 °C) < CO₂/isopentane (60.2 °C) < CO₂/pentane (62.6 °C) < CO₂/methanol (72.78 °C), These trends arise because mixtures whose components have approximate volatilities exhibit smaller temperature glides due to minimal composition shifting across the two-phase region. This low glide temperature reduces the thermal resistance due to mixture effect and increases the heat transfer.

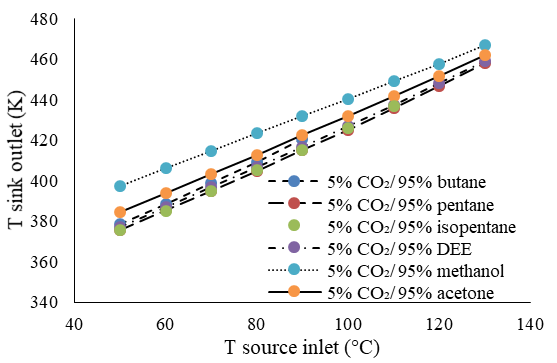

To calculate the selected performance indicators, the present study considered the temperature lift (∆Tlift) and source glide (∆Tsource) of 60K and 10K respectively. The trend of heat sink outlet temperatures of the system for all CO2 based zeotropic refrigerant mixtures is presented in Figure 5, which clearly shows the direct relation between the heat source inlet temperature and the heat sink outlet temperature. Heat sink outlet temperature increases with the rise in heat source inlet temperature. The result indicates that all the selected zeotropic refrigerant mixtures deliver high sink outlet temperatures. At the same source inlet temperature of 90℃ the proposed CO2 based zeotropic refrigerants deliver sink outlet temperature of CO2/butane 420.3K, CO2/pentane 414.9K, CO2/isopentane 415.3K, CO2/DEE 416.7K, CO2/methanol 431.8K, CO2/acetone 422.37K. Based on this result CO2/ (methanol, acetone, butane) mixtures delivers better sink outlet temperature than other proposed refrigerants CO2/methanol have 2.24% increase than CO2/acetone similarly CO2/acetone have 0.49% increase than CO2/butane.

From the proposed CO2 based zeotropic refrigerants CO2/ (pentane, DEE, methanol, and acetone) showed applicability to obtain sink outlet temperature above 150℃ at the same maximum source inlet temperature of. The maximum sink outlet temperature which is delivered by CO2/pentane, CO2/DEE, CO2/methanol, and CO2/acetone were found to be 457.88K, 459.17K, 466.7K, and 461.91K respectively.

The result indicates that higher source inlet temperatures increase the driving potential for heat transfer, thereby raising the sink outlet temperature. These insights highlight that careful selection of zeotropic mixtures enables higher sink outlet temperatures, improving the practical applicability and efficiency of HTHPs.

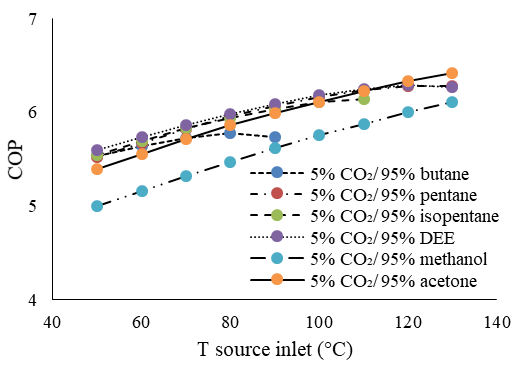

Figure 6 shows the COP of selected refrigerant mixture for various source inlet temperature. As shown in the result, the COP of the system increases when the source inlet temperature increases. This is because an increase in the source inlet temperature, at constant temperature lift and pinch point temperature, results in an elevated evaporator and condenser dew point temperature. This shift leads to a corresponding increase in the evaporator and condenser pressure consequently, the specific compression work decreases. This reduction in compressor work directly contributes to an improvement in the COP, highlighting that the HTHPs operates efficiently when the source inlet temperature of evaporator increases. The COP of above 5 were observed for all refrigerants even at a minimum source inlet temperature of 50°C. At the same source inlet temperature of 90°C, the proposed CO2-based zeotropic refrigerants have COPs of CO2/butane 5.73, CO2/pentane 6.07, CO2/isopentane 6.03, CO2/DEE 6.08, CO2/methanol 5.6, and CO2/acetone 5.99. This result follows the trend in which, at constant source inlet temperatures, the CO2-based zeotropic refrigerants with maximum sink outlet have minimum COP. The higher the sink outlet temperature, the lower the COP [22]. Based on these results, CO2/ (DEE, pentane, isopentane) mixtures have maximum COP compared to other proposed refrigerants. At the same maximum source inlet temperature, the COPs of CO2/pentane, CO2/DEE, CO2/methanol, and CO2/acetone were 6.28, 6.27, 6.11, and 6.41 respectively.

This result indicates that maximum COP is obtained from the CO2/acetone zeotropic mixture, which has a 4.92% increment compared to CO2/methanol. Thus, the outcome of the present model reveals the system can deliver high temperature with high performance using CO2/ acetone zeotropic refrigerant mixture.

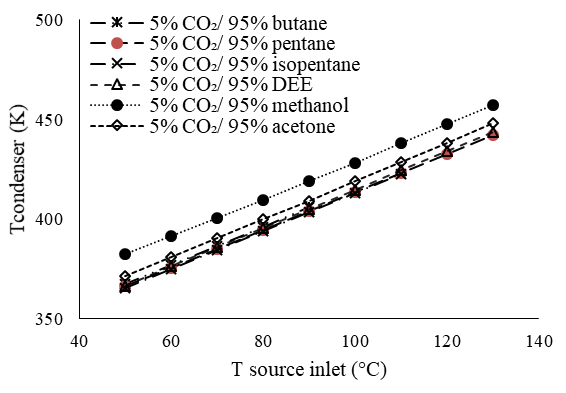

Figure 7 shows that the maximum thermodynamic average temperature of the condenser occurs at the highest source inlet temperature. The results indicate that as the source inlet temperature increases at constant lift and pinch point temperatures, the dew point temperature of condenser and evaporator increase resulting in an increase in the thermodynamic average temperature of the condenser. This implies that operating at higher source temperatures can enhance the energy transfer efficiency of the condenser, supporting more effective heat rejection and overall performance optimization of HTHPs.

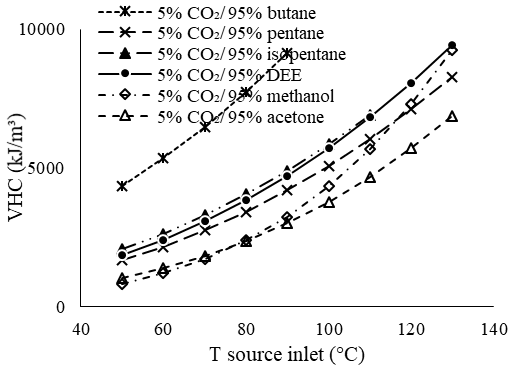

Figure 8 illustrates the VHC of a CO₂/HC zeotropic mixture at different source inlet temperatures the result indicates that as the source inlet temperature increase VHC also increases. VHC measures the refrigerant's ability to absorb heat per unit volume, a critical parameter for compressor design in refrigeration systems. These insights are critical for compressor and system design, indicating that the higher source inlet temperature achieves higher VHC, enabling more compact compressor and efficient HTHPs.

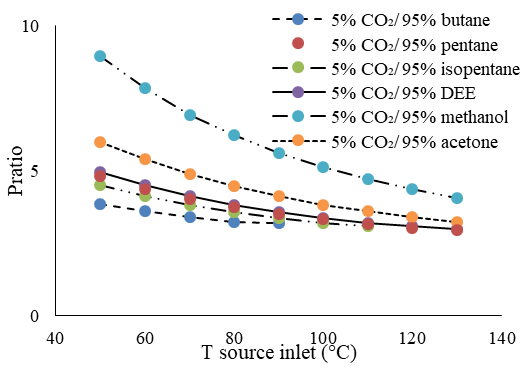

The pressure ratio in a heat pump system, defined as the ratio of condenser pressure to evaporator pressure, is a critical factor influencing system performance, efficiency, and compressor workload. A high-pressure ratio increases compressor power consumption and reduces volumetric efficiency, leading to higher exergy destruction and potential mechanical stress. however, a lower pressure ratio can improve efficiency. Figure 9 shows variation of pressure ratio versus source inlet temperature at constant lift temperature of 60K. The result indicates that pressure ratio has an inverse relation with source inlet temperature. A higher source inlet temperature increases the evaporator temperature and pressure, reducing the pressure ratio. This leads to lower compressor work, improved COP, and higher system efficiency.

The results indicate that CO2/butane has minimum pressure ratio and CO2/methanol has maximum pressure ratio for all variations of source inlet temperature. At the maximum source inlet temperature CO2/acetone has a pressure ratio of 3.21, which is a 20.9% reduction compared with CO2/methanol. The pressure ratio decreases with rising source inlet temperature, as higher evaporator pressures reduce the condenser-to-evaporator ratio, lowering compressor work and enhancing system efficiency. This highlights that selecting CO₂-based zeotropic mixtures with lower pressure ratios can optimize COP and reduce mechanical stress in HTHPs.

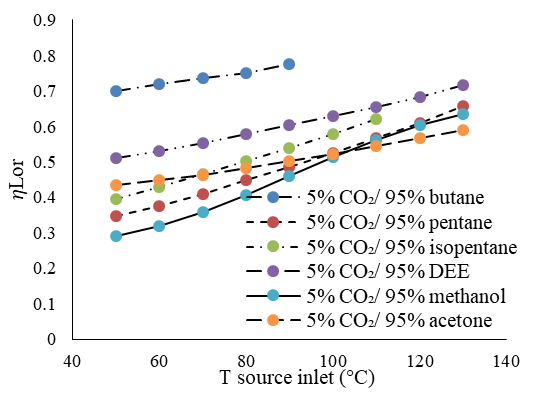

Figure 10 depicts variation of Lorenz efficiency with source inlet temperature at constant ∆Tlift=60K. The result indicates that Lorenz efficiency increases as source inlet temperature increases for all proposed CO2-based zeotropic refrigerants. The results show that CO2/butane has maximum Lorenz efficiency and CO2/methanol has minimum Lorenz efficiency for a source inlet temperature ranging from 50-100°C. At 90°C of source inlet temperature, CO2/butane achieves the maximum Lorenz efficiency of 77.7%, highlighting the importance of mixture selection for maximizing energy utilization in HTHPs.

5. Conclusion

This study evaluated the thermodynamic performance of CO₂-based zeotropic refrigerants for high-temperature heat pump applications. The results demonstrate that the selection of the optimal hydrocarbon based refrigerant mixture significantly influences system efficiency, COP, and heat exchanger performance.

From the study the following conclusions were drawn:

- CO₂/butane is recommended for applications requiring sink outlet temperatures up to 140°C, as it offers the highest Lorenz efficiency (77.7% at 90°C source inlet temperature), contributing to enhance system efficiency.

- CO₂/acetone is the preferred mixture for sink outlet temperatures above 150°C due to its superior COP (6.41 at maximum source inlet temperature), making it suitable for industrial high-temperature heating applications.

- The implementation of these CO₂-based zeotropic mixtures can significantly improve the energy efficiency and sustainability of HTHPs.

- Future work should focus on experimental validation and optimization of system configurations to maximize the benefits of these refrigerant blends in real-world applications.

References

[1] K. M. Tsamos, Y. T. Ge, Id. Santosa, S. A. Tassou, G. Bianchi, and Z. Mylona, “Energy analysis of alternative CO2 refrigeration system configurations for retail food applications in moderate and warm climates,” Energy Convers. Manag., vol. 150, pp. 822–829, Oct. 2017, doi: 10.1016/j.enconman.2017.03.020. View Article

[2] J. Sarkar, S. Bhattacharyya, and M. R. Gopal, “Transcritical Carbon Dioxide Based Heat Pumps: Process Heat Applications,” 2004. View Article

[3] F. Bruno, M. Belusko, and E. Halawa, “CO2 Refrigeration and Heat Pump Systems—A Comprehensive Review,” Energies, vol. 12, no. 15, p. 2959, Jan. 2019, doi: 10.3390/en12152959. View Article

[4] P. Gullo, B. Elmegaard, and G. Cortella, "Energy and environmental performance assessment of R744 booster supermarket refrigeration systems operating in warm climates," Int. J. Refrig., vol. 64, pp. 61-79, Apr. 2016, doi: 10.1016/j.ijrefrig.2015.12.016. View Article

[5] G. Vaccaro, "Refrigeration with eco-friendly fluids. Development of refrigeration systems with CO₂-based refrigerant mixtures.," 2025, Accessed: Oct. 27, 2025. [Online]. Available: https://tesidottorato.depositolegale.it/bitstream/20.500.14242/195685/1/PhD_Thesis_Guglielmo_Vaccaro.pdf View Article

[6] D. Yang, Y. Song, F. Cao, L. Jin, and X. Wang, "Theoretical and experimental investigation of a combined R134a and transcritical CO2 heat pump for space heating," Int. J. Refrig., vol. 72, pp. 156-170, 2016. View Article

[7] K. M. Meshesha, D. Newport, J. Gómez-Hernández, A. Odonovan, and R. Grimes, "Assessment of Blends of CO2 with Hydrocarbons as a Zeotropic Refrigerant for HTHPs," presented at the The 11th World Congress on Mechanical, Chemical, and Material Engineering, Aug. 2025. doi: 10.11159/htff25.177. View Article

[8] J. Sarkar and S. Bhattacharyya, "Assessment of blends of CO2 with butane and isobutane as working fluids for heat pump applications," Int. J. Therm. Sci., vol. 48, no. 7, pp. 1460-1465, 2009. View Article

[9] G. Toffoletti, E. Sicco, G. Cortella, and P. D'Agaro, "Evaluating the use of CO2-Hydrocarbon blends as working fluids in high temperature heat pumps," in Proceedings of 16th IIR-Gustav Lorentzen Conference on Natural Refrigerants, 2024. Accessed: Nov. 13, 2025. [Online]. Available: https://air.uniud.it/handle/11390/1292278 View Article

[10] C. Li, Y. Wang, Q. Guo, Y. Wang, and H. Chen, "High-Temperature Heat Pump Using CO2-Based Mixture for Simultaneous Heat and Cold Energy Reservation," Energies, vol. 16, no. 18, p. 6587, 2023. View Article

[11] F. Ju et al., "Experiment and simulation study on performances of heat pump water heater using blend of R744/R290," Energy Build., vol. 169, pp. 148-156, 2018. View Article

[12] S. Koyama, D. X. Jin, J. Xue, N. Takata, K. Kuwahara, and A. Miyara, "Experimental Study on the Performance of a CO2/DME System," in Proceedings, 2007, pp. 1678-1684. View Article

[13] J. Gómez-Hernández, R. Grimes, J. V. Briongos, C. Marugán-Cruz, and D. Santana, "Carbon dioxide and acetone mixtures as refrigerants for industry heat pumps to supply temperature in the range 150-220 oC," Energy, vol. 269, p. 126821, 2023. View Article

[14] Y. Onaka, A. Miyara, and K. Tsubaki, "Experimental study on evaporation heat transfer of CO2/DME mixture refrigerant in a horizontal smooth tube," Int. J. Refrig., vol. 33, no. 7, pp. 1277-1291, 2010. View Article

[15] C. Ren, Q. Song, S. Sun, C. Zhang, and D. Wang, "Experimental Study on Flow Boiling Heat Transfer of Zeotropic Mixture R290/R601a in a Mini-Channel," Energies, vol. 18, no. 8, p. 2074, 2025. View Article

[16] M. Huber, A. Harvey, E. Lemmon, G. Hardin, I. Bell, and M. McLinden, "NIST Reference Fluid Thermodynamic and Transport Properties Database (REFPROP) Version 10 - SRD 23." National Institute of Standards and Technology, 2018. doi: 10.18434/T4/1502528. View Article

[17] S. Fukuda, C. Kondou, N. Takata, and S. Koyama, "Low GWP refrigerants R1234ze (E) and R1234ze (Z) for high temperature heat pumps," Int. J. Refrig., vol. 40, pp. 161-173, 2014. View Article

[18] C. Arpagaus, F. Bless, M. Uhlmann, J. Schiffmann, and S. S. Bertsch, "High temperature heat pumps: Market overview, state of the art, research status, refrigerants, and application potentials," Energy, vol. 152, pp. 985-1010, 2018. View Article

[19] G. Venkatarathnam and S. Srinivasa Murthy, "Effect of mixture composition on the formation of pinch points in condensers and evaporators for zeotropic refrigerant mixtures: Influence des compositions de mélanges zéotropiques sur la formation de points de pincement dans les condenseurs et les évaporateurs utilisant ces mélanges," Int. J. Refrig., vol. 22, no. 3, pp. 205-215, May 1999, doi: 10.1016/S0140-7007(98)00056-5. View Article

[20] B. Zühlsdorf, J. K. Jensen, and B. Elmegaard, "Heat pump working fluid selection-economic and thermodynamic comparison of criteria and boundary conditions," Int. J. Refrig., vol. 98, pp. 500-513, Feb. 2019, doi: 10.1016/j.ijrefrig.2018.11.034. View Article

[21] J. R. Thome, J. El Hajal, and A. Cavallini, "Condensation in horizontal tubes, part 2: new heat transfer model based on flow regimes," Int. J. Heat Mass Transf., vol. 46, no. 18, pp. 3365-3387, 2003. View Article

[22] J. Navarro-Esbrí, A. Fernández-Moreno, and A. Mota-Babiloni, "Modelling and evaluation of a high-temperature heat pump two-stage cascade with refrigerant mixtures as a fossil fuel boiler alternative for industry decarbonization," Energy, vol. 254, p. 124308, 2022. View Article