Volume 12 - Year 2025 - Pages 482-489

DOI: 10.11159/jffhmt.2025.048

Implementation of Lean Manufacturing to Increase Aircraft Availability and Productivity: a case study

William J. Orbegoso-Alaluna1, Luis A. Zevallos-Bonifacio1, Edilberto M. Avalos-Ortecho2

1,2Carrera de Ingeniería Industrial, Universidad de Lima, Lima, Perú

Av. Javier Prado Este 4600, Santiago de Surco, Lima, Perú 15023

20191441@aloe.ulima.edu.pe; 20202436@aloe.ulima.edu.pe

2eavalos@ulima.edu.pe

Abstract - Aircraft availability is a crucial factor in ensuring the continuity and effectiveness of pilot training programs. In the aeronautical industry, maintenance complexities and operational variables represent challenges to maintaining a constant operational fleet, resulting in economic losses and operational delays. This study aims to address the problem of low aircraft availability in a civil aviation training center by implementing Lean Manufacturing tools to increase aircraft availability. The research demonstrates that by applying techniques such as Total Productive Maintenance (TPM), process automation, and predictive maintenance, it is possible to increase aircraft availability and reduce operating costs. A simulation model was developed using Arena software to validate the impact of these improvements, showing an increase in availability from 60.56% to 83.75%. The results highlight a significant reduction in maintenance downtime, increasing availability by 12% due to a decrease in MTTR from 7.278 Hrs/failure to 3.807 Hrs/Failure and an increase in MTBF from 12.7 Hrs. to 60.5 Hrs., as well as improvements in operational efficiency with an 86.67% improvement in filling out the Aircraft Technical Log (ATL) and a 73.62% improvement in filing flight plans, which contributes to increasing profitability from PEN 29,100 to PEN 52,700.

Keywords: Lean manufacturing, aircraft availability, efficiency, total productive maintenance.

© Copyright 2025 Authors - This is an Open Access article published under the Creative Commons Attribution License terms Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2025-08-25

Date Revised: 2025-09-29

Date Accepted: 2025-12-11

Date Published: 2025-12-22

1. Introduction

Aircraft availability is a determining factor in ensuring the continuity and effectiveness of pilot training programs[1]. In the aeronautical industry, the complexity of maintenance processes and various operational variables present a problem in maintaining a constant operational fleet, affecting operations. [3]. These factors represent losses of between USD 2,500 and USD 5,500 for each reactive maintenance in a small civil aviation school. The implementation of Lean Manufacturing allows the reduction of waste, which allows the reduction of losses. [2]. It is estimated that aircraft availability should be greater than or equal to 80%, which, with the implementation of Lean tools, is possible to increase the current availability by 10% to 20%. [4].

The implementation of Total Productive Maintenance (TPM) allows for improved efficiency in aircraft maintenance processes by reducing downtime and increasing OEE by up to 7% [4][5]. The application of Value Stream Mapping (VSM) led to analyze the current state of the processes and identify the points of improvement where there is no added value through the process efficiency indicator, Lead Time, Tack Time to then resolve improvement opportunities identified in the processes. [6]. Process automation through BPM in combination with Bizagi software allows for improved efficiency in support processes, which contributes to the reduction of operating costs. [7].

An alternative to evaluate the effectiveness of applying a technique to improve a process and when there is a shortage of resources is simulation. The Arena Software allows simulating processes of goods and services, for which the conceptual model As Is and the model with the To Be improvement must be designed, validating inputs and outputs with the Input and Output Analyzer [8].

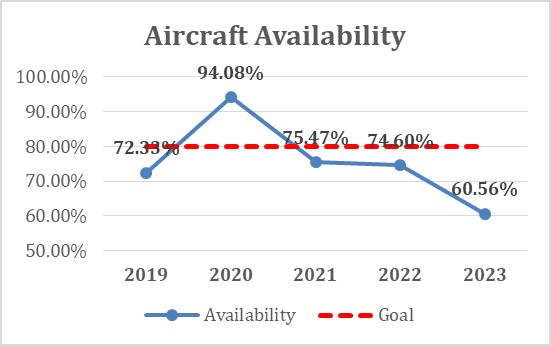

This research aims to solve the problem of low aircraft availability of a company that provides aeronautical training services. During the year 2023, the availability of the aircraft was measured, obtaining a result of 60.56% shown in Figure 1. Considering that the availability of the sector is 80% [9], The identified technical gap is 19.44%, which generates an economic impact of 46,041.32 PEN, a low service level of 49%. The main causes of low availability were identified in an Ishikawa diagram.

The application of the selected Lean tools shows how their use has improved overall efficiency. [10][11] in relation to time, as well as the reduction of the inherent operating costs of aircraft maintenance to increase aircraft availability [12]. Automation is an essential tool today, which allows for better productivity, cost reduction, and lead time in processes [13]. In turn, the implementation of TPM allows increasing availability by reducing the MTTR and increasing the MTBF [14]. It is expected to contribute to a better understanding of the uses of Lean Manufacturing within the aeronautical sector and how to implement them effectively so that costs can be reduced and time optimized within the maintenance process of an aircraft in a growing and difficult to manage sector.

While existing literature extensively covers Lean implementation in large-scale commercial aviation and aerospace manufacturing, there is a notable scarcity of research focused specifically on Civil Aviation Training Centers. Unlike major commercial airlines that possess large fleet redundancies and extensive MRO (Maintenance, Repair, and Operations) networks, training centers operate with distinct constraints: small fleets, high flight frequency, and a direct dependency between aircraft availability and student academic progress.

The objective of this research is to demonstrate that the application of Lean Manufacturing in a pilot training environment allows an increase in aircraft availability from 60.56% to 80% and contributes to increasing the profitability of the business. This study differentiates itself from previous works by combining TPM and process automation specifically tailored to the resource limitations of a small aeronautical school, rather than a large industrial setting. The results will be demonstrated by performing the simulation in ARENA. The following research question will be answered: Does the implementation of Lean Manufacturing increase the availability of aircraft?

This article is structured as follows: abstract, introduction, methodology, results, conclusion, and discussion.

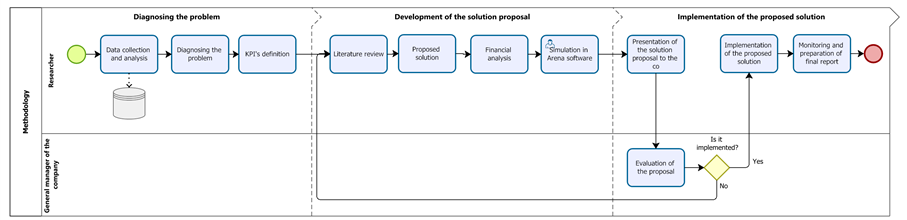

2. Methodology

2. 1. Problem definition and requirements

As demonstrated in the introduction, aircraft availability is 60.56%, with an MTTR of 7.278 Hrs/Failure and an MTBF of 12.7 Hrs, which is insufficient to meet the students' demand and ensure a constant flow of operations. The main causes of the problem were identified in a problem tree diagram whose weightings were performed using a Pareto diagram considering the economic impact of each reason and root cause. The methodology followed in the research is presented in Figure 2.

2. 2. Improvement Proposal

A solution to the low availability of aircraft is the implementation of Lean Manufacturing tools, since, as indicated [15], It allows for the reduction of waiting times for spare parts for aircraft, reduces processes, reduces defects, unnecessary movements, unnecessary transport and improves spare parts inventory management [16].

[17] shows that the implementation of TPM and predictive maintenance with historical failure analysis allows for the reduction of costs and workload, improving the accuracy in fault detection [18] and the efficiency of maintenance performance by up to 20%. [19] proposes a predictive maintenance model since the availability of an aircraft decreases over time due to its high use, the stress to which the aircraft is subjected and its age. Using machine learning [20] , the maintenance history of the aircraft and the flight metrics are analyzed, finding a correlation in the metrics obtained and accurately predicting their availability in the future. [21] Proposes the combination of TPM with SMED, which allows increasing OEE by 32%. [22] validates that automation allows the reduction in Lead Time and manual tasks. [23] Develops research on the implementation of an approximate dynamic programming methodology for scheduling aircraft maintenance inspections with the aim of reducing the total wasted utilization interval between maintenance inspections, thereby increasing aircraft availability without compromising air safety. [24] proposed the aircraft failure rate prediction method based on complementary set empirical mode decomposition function and a combined model. The experiment results proved that the proposed model was more accurate for failure prediction. [25] The efficiency and effectiveness of using algorithmic models [26] in maintenance planning to increase aircraft availability is demonstrated [27].The use of TPM and Lean Manufacturing tools is proposed to increase a company's OEE, achieving an increase of 7.83%.

2. 3. Unit of analysis

The consistency matrix was created for the identification of the analysis unit as shown in Table 1, with the instruction program being the analysis unit.

Table 1. Consistency Matrix

|

PROBLEM |

MAIN OBJECTIVE |

HYPOTHESIS |

|

Is there any relationship between Lean tools and increased aircraft availability in an aeronautical company? |

Implement Lean tools to increase aircraft availability in a company in the aeronautical sector, using data analysis tools, process optimization and continuous improvement |

The implementation of Lean tools in an aeronautical company increases aircraft availability. |

The variables for the problem are:

X1: Implementation of Lean tools

Y1: Training program

The data collection technique used was the Aircraft Technical Log (maintenance log), interviews with the general manager and time recording with a stopwatch.

2. 4. Statistical Analysis of data

At this stage, the distribution probabilities associated with the inter-arrival times were determined. The distributions were validated using the Chi-square and Kolmogorov tests. The times of the main processes to be analyzed are shown in Table 2. The main bottleneck is found in the aircraft repair process, with a mean of 14.3 hours and a standard deviation of 4.16.

Table 2. Activity time

|

Process |

Distribution |

Time |

Unit |

|

ATL record |

Normal |

Mean (30.4), Std Dev (1.74) |

min/aircraft |

|

File Flight Plan |

Normal |

Mean (13.1), Std Dev (1.28) |

min/aircraft |

|

Aircraft repair |

Normal |

Mean (14.3), Std Dev (4.16) |

hours/aircraft |

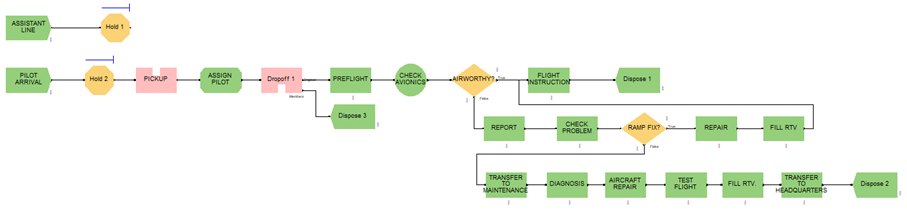

6. Simulation Model

The AS IS model of the simulation of the instruction process was conducted in the Arena software version 16.10.00003 using the data collected with a total of 45 replicas and validating that the result of the simulation is a representation of reality, considering the following indicators:

- Aircraft availability

- Average waiting time for students to be available for aircraft.

- Average time for filling out ATL.

- Average time for filling out flight plans.

- Income from flights conducted satisfactorily.

- Losses from flights postponed due to reactive maintenance.

The simulation model was constructed reflecting the specific operational reality of the case study company. The system boundaries and assumptions for the simulation are defined as follows:

- Fleet and Personnel: The model simulates the operation of a fleet of 3 instructional aircraft and a staff of 3 flight instructors, catering to an annual demand of 45 students.

- Operational Constraints: The flight dispatching logic is modeled based on resource availability. Students are not processed in a standard arrival queue; instead, they remain in a waiting state until an instructor becomes available to call them for a flight. The model specifically measures this waiting time (delay) generated by the limited availability of the 3 aircraft and 3 instructors.

- Stochastic Variables: Failure generation is modeled based on historical failure rates (MTBF), while repair times follow the distributions identified in the statistical analysis (MTTR).

- Scope Limitations: For the simulation, weather conditions were treated as constant to isolate the variable of maintenance efficiency. Scheduling conflicts were resolved via First-In-First-Out (FIFO) logic within the student group.

Finally, the AS IS simulation model is shown in Figure 3.

3. Results

The following results were obtained with a confidence level of 95% as result of the proposed model shown in Table 3.

Table 3. To Be Simulation Results

|

INDICATOR |

INTERVAL |

|

Aircraft availability |

[0.807, 0.868] |

|

Average waiting time for students to be available for aircraft |

[5.32, 9.17] hours |

|

Average time for filling out ATL |

[4.0344, 4.1256] minutes |

|

Average time for filling out flight plans |

[1.686, 5.97] minutes |

|

Income from flights carried out satisfactorily |

[51 792, 53 608] PEN |

|

Losses from flights postponed due to reactive maintenance |

[11 310, 14 290] PEN |

For the interpretation and analysis of the results obtained, the Output Analyzer was used at a confidence level of 95%. The main indicators were analyzed, obtaining the results shown in Table 4.

Table 4. Output Analyzer comparison

|

INDICATOR |

ORIGINAL INTERVAL |

TO BE INTERVAL |

|

Aircraft availability |

[0.63, 0.724] |

[0.807, 0.868] |

|

Average time for filling out flight plans |

[13.5, 15.54] min |

[2.29, 5.97] min |

|

Average time for filling out ATL |

[30.3, 30.9] min |

[4.04, 4.29] min |

The implementation of certain TPM pillars managed to increase aircraft availability from 60.56% to 83.75%. This 16.05% net increase in availability translates into a tangible operational improvement. With the fleet available for a larger portion of the operational window, the center can execute more flights per day, thereby increasing the daily sorting rate. This reduction in downtime directly alleviates the bottleneck in student progression, allowing the center to clear the backlog of pending flight hours and graduate students within the estimated academic timeframe and increase profits.

Maintenance personnel planned periodic inspections every 25 flight hours, monitoring the wear and tear of aircraft parts and components. This allowed reducing the number of aircraft downtimes due to failures [28]. Thanks to periodic inspections, the MTBF was increased from 12.7 hours to 50.66 hours. In turn, the MTTR decreased from 14.6 hours to an average of 1.5 hours. Finally, autonomous maintenance by flight instructors has allowed the aircraft to be kept in optimal condition for operations.

A database was also implemented, which contains the registration of the company's aircraft, flight instructors, students, airports and the historical tach time of the aircraft. An Excel program with VBA code has been developed to reduce the Lead Time in the Aircraft Technical Record (ATL), transforming the manual process into an automated one [29]. This process was carried out manually by adding the times with a calculator and with a high error rate, cancelling some ATLs due to errors in data entry. In response to this, the ATL was digitalized [30]in Microsoft Excel, automatically calculating the flight times of the aircraft. In turn, the VBA code allows the automatic change of the name of the sheet with the date filled in the ATL and adding a new page while keeping the necessary data from the previous page. Figure 4 shows the automation of the ATL filling. The results of the implementation managed to reduce the average ATL filling time from 30 minutes to 4 minutes, which resulted in an improvement of 86.67%. In turn, no cancellations were recorded in the ATLs, since the data is calculated automatically.

For the company's flight plans, these were filled out from scratch and a flight plan took 15 minutes on average to complete. In response to this, a VBA program was created in Excel with an incorporated database. The database allows the display of a list for the aircraft to be used, the flight rules, flight level, the departure and arrival aerodromes, which have predefined routes, estimated time enroute and the pilots and passengers who will be on board the aircraft. In turn, the program with macros allows the automatic change of the page name and the export of the flight plan with the standardized name, achieving a reduction in the preparation of the flight plan from 15 minutes to 4 minutes on average, which represents an improvement of 66.67%. Figure 5 shows the automation of the flight plan filling.

Table 5. Results

|

Process |

Original |

Proposed |

Improvement |

|

Availability |

67.7% |

83.75% |

16.05% |

|

ATL filling |

30.60 min |

4.08 min |

86.67% |

|

File Flight Plan |

14.52 min |

3.83 min |

73.62% |

The effectiveness of the Lean Manufacturing Tools implementations was assessed through a quality inspection in August 2025, which identified only one minor non-conformance. The OEE increased from a baseline of 0.275 in 2023 to 0.729 in 2025. This increase in OEE directly contributes to increased aircraft availability by reducing maintenance turnaround times and the automation of key processes.

4. Conclusion

The results obtained regarding the increase in aircraft availability from 67.7% to 83.8% confirm the effectiveness of the implementation of TPM and automation.

The use of Arena software has proven to be important in predicting the results of the implementation of improvements, allowing the optimization of solution proposals to obtain better results.

The automation of the ATL filling processes and flight planning allows aircraft to remain operational for longer by reducing the Lead Time from 14.52 to 3.83 minutes for the preparation of the flight plan, as well as the reduction of ATL filling Lead Time from 30.6 to 4.08 minutes. This had a significant impact on the reduction of pilot waiting times to use the aircraft, reducing it from 14.3 hours to 7.25 hours. Validating that automation allows reducing Lead Time [11].

The implementation of TPM proved to be effective in reducing the MTTR from 7,278 Hrs/Failure to 3,807 Hrs/Failure and increasing the MTBF from 12.7 Hrs to 60.5 Hrs, which allowed increasing aircraft availability up to 83.75%, exceeding the industry availability set at 80%.

5. Limitations

It is important to acknowledge the limitations of this research to provide context for the results. First, the study focuses on a single Civil Aviation Training Center with a small fleet (3 aircraft), which may limit the generalizability of the findings to larger MROs or commercial airlines with different economies of scale. Second, the simulation assumes a simplified supply chain for spare parts; in reality, external logistics delays could impact MTTR outside of the proposed Lean improvements. Finally, the successful implementation of TPM assumes a cultural adaptation by the staff, a qualitative variable that is difficult to fully represent in a quantitative discrete event simulation.

References

[1] S. Ichou and Á. Veress, "Satisfying the needs for highly qualified engineering staff in a disruptively changing aircraft industry with special care for MRO sector," Aircr. Eng. Aerosp. Technol., vol. 96, no. 7, pp. 900-911, 2024, doi: 10.1108/AEAT-12-2023-0347 View Article

[2] J. A. Jordan, A. Etemadi, and M. W. Grenn, "Predicting KC-135R Aircraft Availability With Aircraft Metrics," IEEE Trans Eng Manag, vol. 69, no. 6, pp. 3864-3873, Dec. 2022, doi: 10.1109/TEM.2021.3059372. View Article

[3] B. A. Salazar, B. Ormeño-Soto, and A. Flores-Perez, "Proposal for optimization of inspections of electric poles using Lean tools and Last Planner System. An empirical research in Peru," in Proceedings of the LACCEI international Multi-conference for Engineering, Education and Technology, 2023. View Article

[4] V. Crute, Y. Ward, S. Brown, and A. Graves, "Implementing Lean in aerospace - Challenging the assumptions and understanding the challenges," Technovation, vol. 23, no. 12, pp. 917-928, 2003, doi: 10.1016/S0166-4972(03)00081-6. View Article

[5] L. Lucantoni, S. Antomarioni, F. E. Ciarapica, and M. Bevilacqua, "A data-driven framework for supporting the total productive maintenance strategy," Expert Syst Appl, vol. 268, 2025, doi: 10.1016/j.eswa.2024.126283. View Article

[6] M. Rakyta, P. Bubenik, V. Binasova, G. Gabajova, and K. Staffenova, "The Change in Maintenance Strategy on the Efficiency and Quality of the Production System," Electronics (Basel), vol. 13, no. 17, p. 3449, Aug. 2024, doi: 10.3390/electronics13173449. View Article

[7] C. D. Bloomquist, L. Holtz, A. M. Lampe, and C. T. Carmichael, "Case study in using value stream mapping in online graduate education," Eval Program Plann, vol. 105, p. 102447, Aug. 2024, doi: 10.1016/j.evalprogplan.2024.102447. View Article

[8] H. S. Mamede, C. M. Gonçalves Martins, and M. Mira da Silva, "A lean approach to robotic process automation in banking," Heliyon, vol. 9, no. 7, p. e18041, Jul. 2023, doi: 10.1016/j.heliyon.2023.e18041. View Article

[9] A. S. M. E. Dias et al., "Utilization of the Arena simulation software and Lean improvements in the management of metal surface treatment processes," Procedia Comput Sci, vol. 204, pp. 140-147, 2022, doi: 10.1016/j.procs.2022.08.017. View Article

[10] G. Arcidiacono, A. Antonacci, and J. Antony, "The r-evolution of Lean Six Sigma from Industry 4.0 to Society 5.0: Excellence 5.0," International Journal of Quality and Reliability Management, 2025, doi: 10.1108/IJQRM-11-2024-0415. View Article

[11] E. J. Knoblock et al., "Intelligent Spectrum Management for Future Aeronautical Communications," IEEE Aerospace and Electronic Systems Magazine, vol. 38, no. 5, pp. 46-59, 2023, doi: 10.1109/MAES.2022.3233817. View Article

[12] S. Yan, C.-Y. Chen, and J.-H. Yuan, "Long-term aircraft maintenance scheduling for an aircraft maintenance centre: A case study," Int. J. Appl. Manag. Sci., vol. 1, no. 2, pp. 143-159, 2008, doi: 10.1504/IJAMS.2008.021098. View Article

[13] Y. Asano, K. Okada, S. Nakagawa, N. Yoshie, and J. Shiomi, "Automation of polymer pressing by robotic handling with in-process parameter optimization," Rob Auton Syst, vol. 185, p. 104868, Mar. 2025, doi: 10.1016/j.robot.2024.104868. View Article

[13] S. Castañeda, S. Rodriguez, O. Yildiz, D. Aranda, and J. C. Alvarez, "Increase of the Availability of Machinery in a Food Company Applying the TPM, SMED and RCM Methodologies," International Journal of Engineering Trends and Technology, vol. 72, no. 8, pp. 128-138, Aug. 2024, doi: 10.14445/22315381/IJETT-V72I8P114. View Article

[14] A. Korchagin, Y. Deniskin, I. Pocebneva, and O. Vasilyeva, "Lean Maintenance 4.0: implementation for aviation industry," Transportation Research Procedia, vol. 63, pp. 1521-1533, 2022, doi: 10.1016/j.trpro.2022.06.164. View Article

[15] K. CAO, Y. ZHANG, and J. FENG, "Failure rate analysis and maintenance plan optimization method for civil aircraft parts based on data fusion," Chinese Journal of Aeronautics, Sep. 2024, doi: 10.1016/j.cja.2024.08.050. View Article

[16] J. Albano, A. Rahn, J. Bachmann, and G. Wende, "Life cycle inventories for aviation: Background data, shortcomings, and improvements," Clean. Eng. Technol., vol. 22, 2024, doi: 10.1016/j.clet.2024.100813. View Article

[17] J. A. Zegarra-Silva, M. A. Caceres-Larco, and A. Flores-Perez, "Improvement proposal to increase the OEE in a mechanical press in the metalworking sector through SMED and TPM," in 2023 9th International Conference on Innovation and Trends in Engineering, CONIITI 2023 - Proceedings, 2023. doi: 10.1109/CONIITI61170.2023.10324265. View Article

[18] J. Aust, A. Mitrovic, and D. Pons, "Comparison of visual and visual-tactile inspection of aircraft engine blades," Aerospace, vol. 8, no. 11, 2021, doi: 10.3390/aerospace8110313. View Article

[19] Q. Deng and B. F. Santos, "Lookahead approximate dynamic programming for stochastic aircraft maintenance check scheduling optimization," Eur J Oper Res, vol. 299, no. 3, pp. 814-833, Jun. 2022, doi: 10.1016/j.ejor.2021.09.019. View Article

[20] Q. Li and R. Jing, "Determinants of travel satisfaction for commercial airlines: A data mining approach," Eng. Appl. Artif. Intell., vol. 133, 2024, doi: 10.1016/j.engappai.2024.108597 View Article

[21] W. Li and N. Hou, "Aircraft Failure Rate Prediction Method Based on CEEMD and Combined Model," Sci Program, vol. 2022, pp. 1-19, Jun. 2022, doi: 10.1155/2022/8455629. View Article

[22] G. Cha, J. Park, and I. Moon, "Military aircraft flight and maintenance planning model considering heterogeneous maintenance tasks," Reliab Eng Syst Saf, vol. 239, p. 109497, Nov. 2023, doi: 10.1016/j.ress.2023.109497. View Article

[23] H. Avila-Pisco, D. A. Chiok-Gonzales, and A. E. Flores-Perez, "Application of TPM and Lean Manufacturing tools to increase OEE. An empirical investigation in the Peruvian textile industry," in 2023 9th International Conference on Innovation and Trends in Engineering, CONIITI 2023 - Proceedings, 2023. doi: 10.1109/CONIITI61170.2023.10324213. View Article

[24] A. Wali, N. A. Mufti, and M. A. Ali, "Enhancing overall equipment effectiveness through lean digitization: a longitudinal study in tractor manufacturing," International Journal of Productivity and Performance Management, 2025, doi: 10.1108/IJPPM-09-2024-0651. View Article

[25] G. B. Benitez, D. Biondo, J. F. C. Seelent, and D. A. Kai, "Investigating the effect of Industry 4.0 technologies on Lean bundles: a stakeholder perspective for quality improvement," Journal of Manufacturing Technology Management, vol. 36, no. 5, pp. 961-984, 2025, doi: 10.1108/JMTM-07-2024-0409. View Article

[26] M. Dai, "A hybrid machine learning-based model for predicting flight delay through aviation big data," Sci. Rep., vol. 14, no. 1, 2024, doi: 10.1038/s41598-024-55217-z. View Article

[27] E. A. Pereira Barreto, F. T. M. T. M. Abrahão, and W. Olivares Loesch Vianna, "Aircraft routing problem model for fractional fleets using fault prognostics," J. Qual. Maint. Eng., vol. 27, no. 3, pp. 517-536, 2021, doi: 10.1108/JQME-06-2020-0053. View Article

[28] J. C. da Silva, A. Barqueira, L. B. Magalhães, and L. F. F. M. Santos, "Human fatigue in the aircraft maintenance environment," Saf. Sci., vol. 180, 2024, doi: 10.1016/j.ssci.2024.106634. View Article

[29] A. G. Ladera-Mejia, X. S. Pun-Gutierrez, J. C. Quiroz-Flores, and A. E. Flores-Perez, "Digital Transformation Model Based on Business Process Management and Lean Manufacturing to Increase the Productivity of the Administrative Area of a Peruvian Aeronautical Company," in ACM International Conference Proceeding Series, 2022, pp. 145-153. doi: 10.1145/3568834.3568852. View Article

[30] S.-H. Chung, "Applications of smart technologies in logistics and transport: A review," Transp. Res. Part E Logist. Transp. Rev., vol. 153, 2021, doi: 10.1016/j.tre.2021.102455 View Article