Volume 12 - Year 2025 - Pages 440-446

DOI: 10.11159/jffhmt.2025.044

Study Of Turbulent Flow Behavior Over Four In-Line and Staggered Cylinders

Yacine Kahil1,2, Abdelkrim Benlefki1,2, Zakaria Rahmani1,2, Djilali Zerrouki3, Tayeb Yahiaoui3

1Tissemsilt University - Ahmed Ben Yahia ElWancharissi, Department of Civil, Mechanical and Transport Engineering

Tissemsilt, Algeria 38000

kahil.yacine@univ-tissemsilt.dz; benlefki.abdelkrim@univ-tissemsilt.dz; rahmaniz784@gmail.com; djilali.zerrouki@gmail.com; yahiaoui_tayeb@yahoo.fr

2University of Science and Technology - Mohamed Boudiaf, Applied Mechanics Laboratory

Oran, Algeria 31000

3University of Science and Technology - Mohamed Boudiaf, Laboratory of Maritime Sciences and Engineering

Oran, Algeria 31000

Abstract - A numerical study was performed to investigate the behavior of an incompressible turbulent flow around four cylinders in a square configuration at a Reynolds number of Re = 3000. The study is performed in order to explain the flow dynamics in tube bundles. Using the Reynolds-Averaged Navier-Stokes (RANS) approach with the k-ω SST turbulence model, the computations were performed using the open source and free software Code_Saturne. Two configurations are analyzed: in-line (α = 0°) and staggered (α = 45°), both with a spacing ratio of P/D = 1.5. The results of the first configuration were validated by comparison with the available experimental and numerical data. The bistability phenomenon was shown based on the different fields of velocity in the in-inline configuration. The analysis of the results of the staggered configurations led to the conclusion that the effect of new configurations on the flow dynamics is well demonstrated by an observation of a jet flow which is distinct from the regular gap flow, characterized by a narrow width and high velocity. Altering the wake shape can cause significant variations in the magnitude and direction of the jet flow, resulting in potential structural vibrations that must be considered in practical engineering applications.

Keywords: CFD, Code_Saturne, turbulent flow, tube bundle, bistability.

© Copyright 2025 Authors - This is an Open Access article published under the Creative Commons Attribution License terms Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2025-04-11

Date Revised: 2025-08-26

Date Accepted: 2025-11-17

Date Published: 2025-12-12

1. Introduction

The study of flows around cylinders offers important insights for optimizing structures subjected to fluid flows. Jet flow can induce destructive vibrations in a heat exchanger by creating fluid-structure interactions. This vibrational effect is caused by mechanisms such as vortex shedding or turbulent buffeting and must be considered during design, along with heat transfer and pressure drop, to prevent fatigue and potentially catastrophic failure. Mitigating these issues may involve reviewing the flow limits and exchanger geometry.

Flow around one cylinder has been the subject of several studies (Adobes et al. [1], Kahil [2]), where the flow behavior has been investigated. For flow studies around multiple cylinders, the pitch-to-diameter ratio P/D and the alignment angle α are essential parameters for understanding the dynamics of fluid flow around the cylinders. The P/D ratio refers to the distance between the centers of the two cylinders divided by their diameters. This parameter plays a crucial role in determining the flow pattern and the extent of the wake zone behind the cylinders. On the other hand, the alignment angle α between the two cylinders and the cross-flow direction can significantly affect the pressure distribution around the cylinders and lead to changes in the flow structure.

Experimentally, the flow around tandem and staggered cylinders has been extensively studied, with investigations into the gap between cylinders and the Reynolds number. Alam et al. [3] investigated the flow characteristics and fluid forces acting on two circular cylinders arranged in various staggered configurations. They found that the lift forces mainly depended on the gap flow between the cylinders at small gap widths, regardless of the staggered angle. The maximum fluctuating drag force acting on the downstream cylinder occurred at an angle of 10 and gap widths of 2.4 to 3.0. Studies on three and four cylinders were conducted in both in-line and staggered arrangements, where the effects of cylinder spacing and Reynolds number were analyzed. Paula et al. [4] investigated the bistability phenomenon around three cylinders in two triangular arrangements. The results identified the presence of bistable flow in the configuration where one cylinder is upstream and two are downstream. The study conducted by Pouryoussefi et al. [5] examined the impact of cross-flow on the flow interference between three cylinders arranged in an equilateral-triangular pattern of equal diameter, as well as between four cylinders arranged in a square pattern, with P/D spacing ratios varying from 1.5 to 4 at a subcritical Reynolds number of 6.08×104. The results showed that the aerodynamic coefficients were significantly affected by changes in P/D. Moreover, decreasing the P/D value amplified the effects of flow interference between the cylinders. Several studies have examined the impact of geometric parameters on the flow pattern transitions around four cylinders arranged in an in-line and staggered square configuration (Lam et al. [6], Zhou et al. [7]). Their results showed that the development of free shear layers around the cylinders was significantly influenced by the spacing ratio, which, in turn, has a considerable impact on the force and pressure characteristics of the four cylinders. The results also showed the presence of bistable flow when the spacing ratio was set to P/D = 1.5.

Regarding numerical studies, Afgan et al. [8] used the dynamic Smagorinsky model (LES) to simulate the flow around two side-by-side cylinders with different pitch-to-diameter ratios at a Reynolds number of 3000. The study revealed that at low gap ratios, the cylinders behaved as a single body with top-to-bottom vortex shedding, while at intermediate gap ratios, a biased flow behavior was observed with a bistable flow pattern. Finally, at higher gap ratios, the cylinders behaved as two independent cylinders with symmetrical wake patterns and anti-phase vortex shedding. Tong et al. [9] presented a numerical study of the steady flow around two circular cylinders with various arrangements at a low subcritical Reynolds number of Re = 103. The study examined the P/D ratio, ranging from 1.5 to 4, and the angle α, ranging from 0° to 90°. The results showed a significant change in the pressure distribution on each cylinder with changes in arrangement, particularly when P/D = 3 and α < 60°, which resulted in movements of the stagnation points and variations in pressure distribution at the cylinder surface. Rahmani et al. [10] numerically modeled the flow around four cylinders arranged in a square configuration using RANS. They found that the P/D = 1.5 configuration exhibited three biased flow modes, designated as modes 1, 2, and 3.

Increased computer power and the development of numerical methods have made it possible to perform 3D flow calculations in various configurations while taking into account the effects of viscosity and turbulence. These advances have made Computational Fluid Dynamics (CFD) an increasingly important tool for the development and optimization of various industrial processes. Among the wide range of known computational codes, it is important to note that all the numerical tools used to generate and analyze the results are open source (free numerical models). The meshes introduced in the computational code were generated and designed using the Gmsh mesh generator [11], and the entire numerical part was done by Code_Saturne [12]. The analysis of the computational code results was visualized and processed using EnsightFree [13].

This work contributes to our understanding of flow behavior in in-line and staggered tube bundles. The investigation method is based on a numerical approach (RANS). The industrial context is well defined, directly connected to applications related to tube bundles of heat exchangers.

2. Case setup

2. 1. Computational details

The design of geometries and the preprocessing of the simulations are presented in this part. The free mesh generator GMSH is used in order to produce meshes. In addition, the two free software; “Code_Saturne” for the processing and “EnsightFree” for the post-treatment of the results, are used.

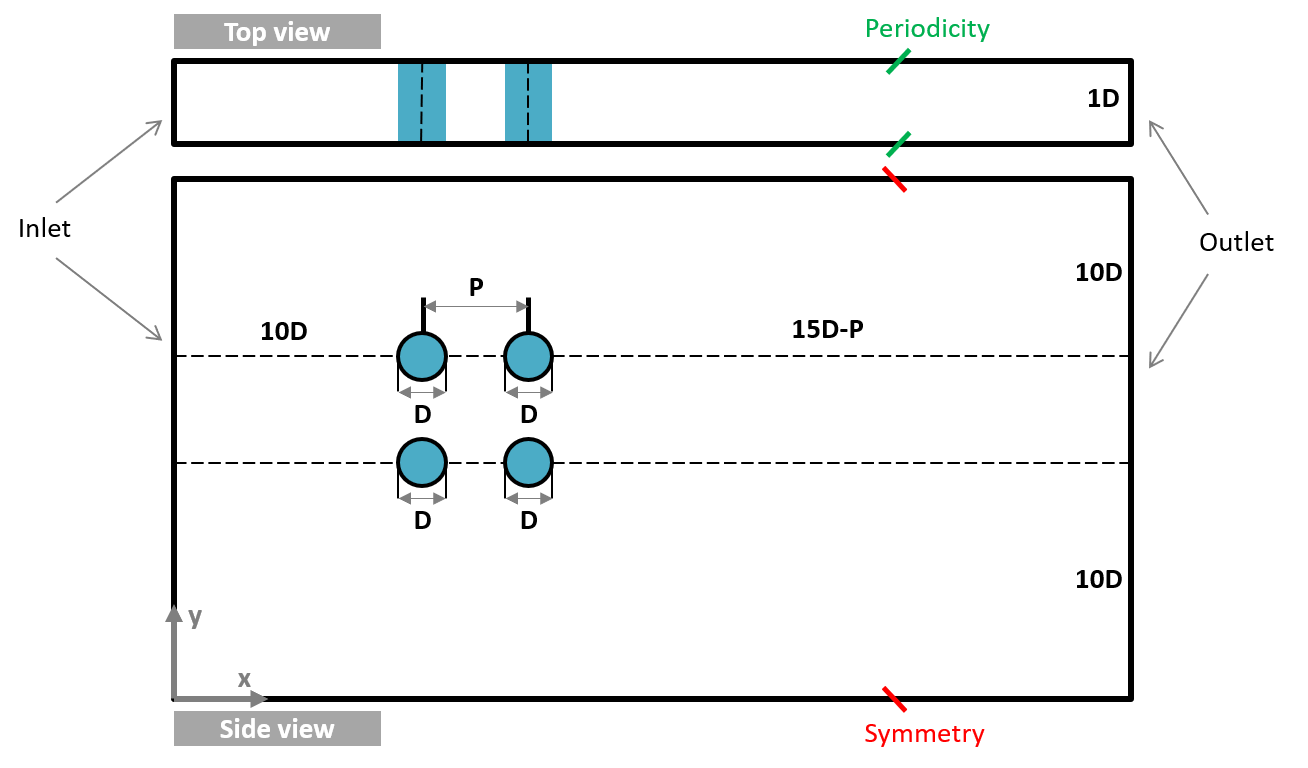

(a) in-line configuration, (b) staggered configuration.

Figure 1 shows the configuration of four cylinders in a square arrangement with a spacing of P/D = 1.5 (measured spacing ratio between the center of the cylinders and the diameter). The compute domain dimensions are 25D in the X direction, 20D in the Y direction, and 1D in the Z direction. The length upstream of the cylinder is 10D, and at the entrance a uniform speed is imposed. Periodicity was applied in the Z direction, simulating flow in turbulent conditions for an incompressible fluid without heat transfer. The analysis is done for a Reynolds number (Re = 3000).

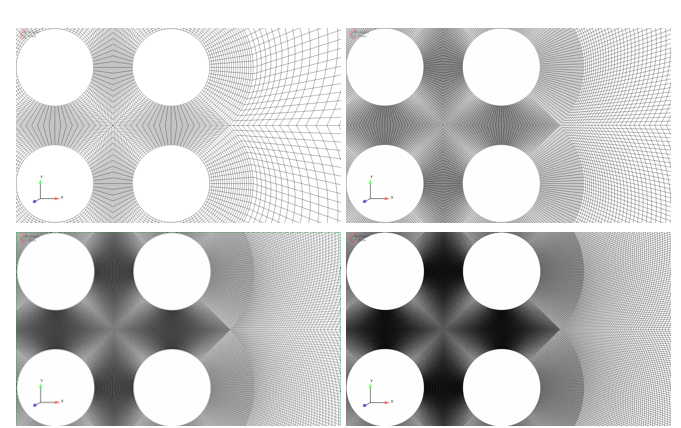

Figure 2 shows the different configurations of the mesh according to the progression factors. A mesh sensitivity study was carried out in order to validate the numerical results with the experimental studies of Lam et al. [10] and to properly adapt the mesh. This study consists of comparing four meshes of different densities (see table 1).

(a) Coarse, (b) medium, (c) fine and (d) very fine.

Table 1. Number of cells in each direction for different meshes.

|

Type of mesh |

N cells (Nx * Ny) |

|

Coarse |

12800 |

|

Medium |

51200 |

|

Fine |

115200 |

|

Very fine |

204800 |

Figure 3 shows the selected meshes (fine) for the two configurations (inline and staggered), for all computations of the study.

(a) in-line configuration, (b) staggered configuration.

2. 2. Governing equations and turbulence model

Code_saturne is an open-source program, developed primarily by EDF, intended for computational fluid dynamics (CFD) simulations. This software solves the Navier-Stokes equations for two-dimensional and three-dimensional flows, whether laminar or turbulent, steady or unsteady, incompressible or slightly compressible, and isothermal or non-isothermal. In addition, it handles the transport of scalar quantities. This system operates based on the finite volume method, which supports unstructured meshes comprising a variety of cell types such as hexahedra, tetrahedra, prisms, pyramids, and polyhedra. Although the majority of models rely on cell-centered and finite volumes that are arranged coherently.

The current work is done in the frame of Reynolds-averaged Navier–Stokes. The RANS equations are time-averaged equations of motion for fluid flow:

The turbulence model used is the k-ω SST (Shear Stress Transport). The latter combines the original Wilcox k-ω model, which is effective near the walls, and the standard k-ε model, effective away from the walls, using a blending function. The formulation of turbulent viscosity is modified to take into account the transport effects of turbulent shear stress.

2. 3. Mesh dependency test

The choice of mesh refinement is a delicate problem. It is recommended to create a sufficiently fine grid in order to ensure the accuracy of the results and to reproduce all the phenomena without causing excessively long computation time. Mesh adaptation is an essential step to determine the optimal model. In general, the mesh structure is refined near the walls and even in the recirculation regions in order to correctly simulate the displacement in the dynamic boundary layers, as well as to capture the regions of high gradients. The improvement of the grid used should not lead to a significant change in the results.

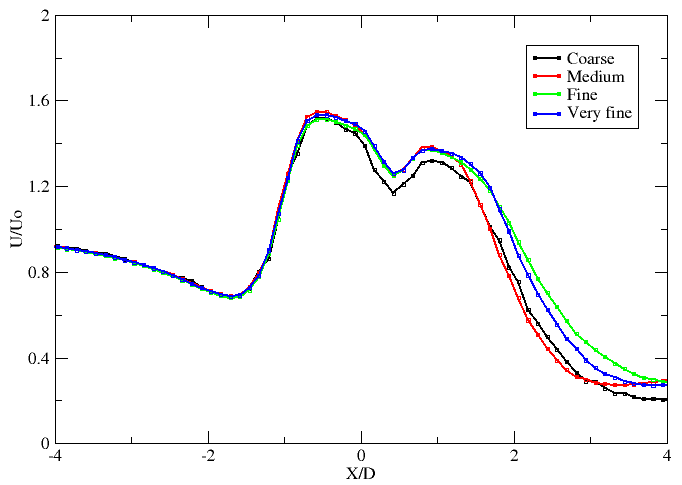

The simulations ran with different mesh resolutions (coarse, medium, fine, and very fine) to determine the mesh sensitivity and obtain accurate results. The optimal mesh chosen in the validation case was maintained for the other configurations. A comparison of the mean streamwise velocity along the centerline Y/D = 0 for the in-line configuration is presented in figure 4. From X/D = 2-4, the mean streamwise velocity varies significantly with changes in mesh resolution from coarse to fine mesh and negligible change between the fine and the very fine mesh. Therefore, the fine mesh was selected for the current study, which offers several advantages, such as saving time, accurate results, and requiring fewer computational resources.

3. Results and discussion

3. 1. In-line configuration

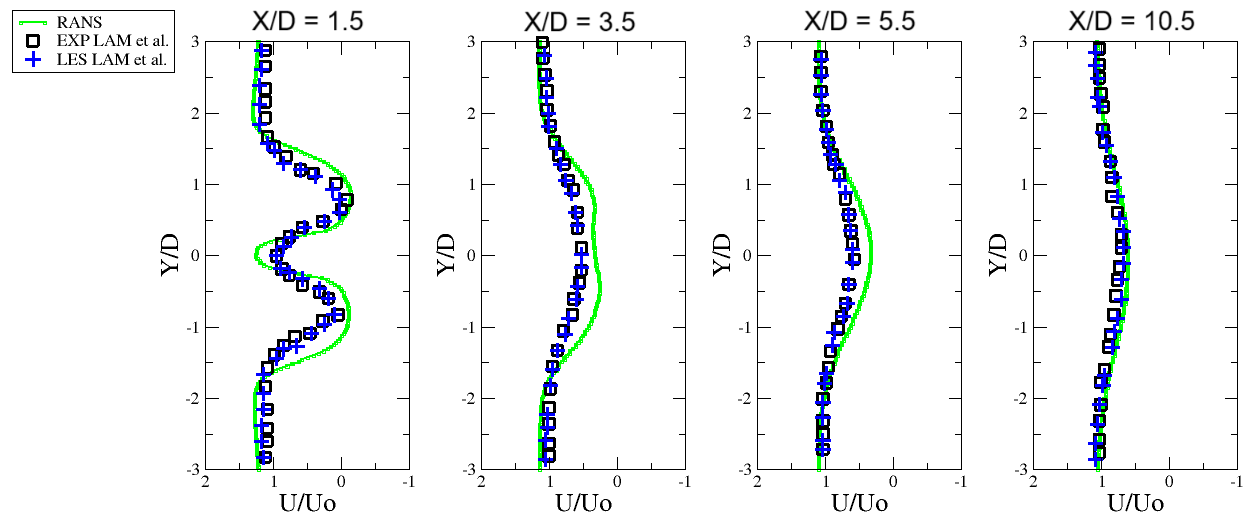

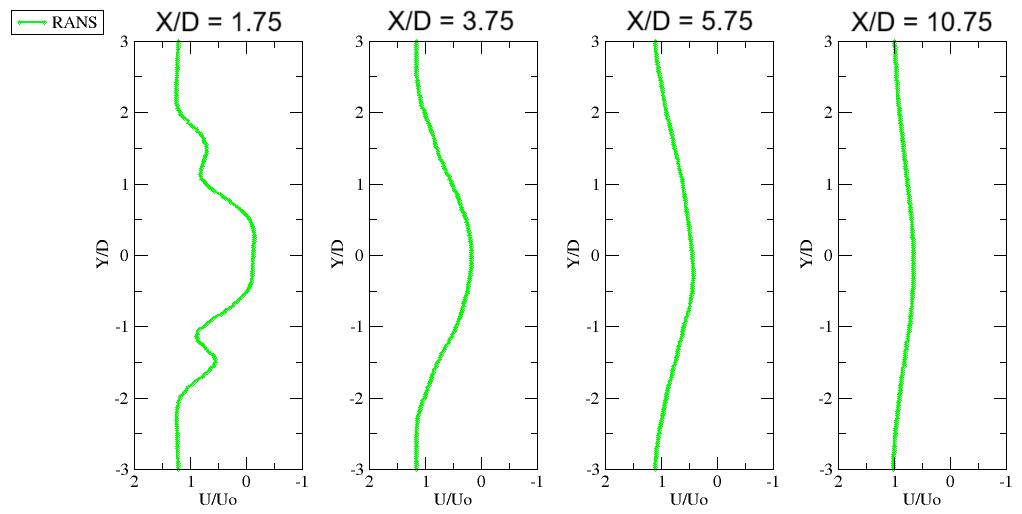

Figure 5 shows the distribution of the non-dimensionalized mean streamwise velocity U/U0 in the wake of the four cylinders in an in-line configuration at P/D = 1.5 with a comparison of the results of Lam et al. [10] at different X/D values. The comparison shows a good agreement with the experimental and numerical results.

The in-line four-cylinder array can be viewed as either two cylinders in tandem arranged in parallel rows or as two cylinders side-by-side arranged in parallel columns. Elongated chains of vorticity are observed in the shear layers that separate from the upstream cylinders (cylinders 1 and 2). The vortices primarily wrap around the downstream cylinders (cylinders 3 and 4) and are linked to alternate vortices that form downstream of the cylinder array.

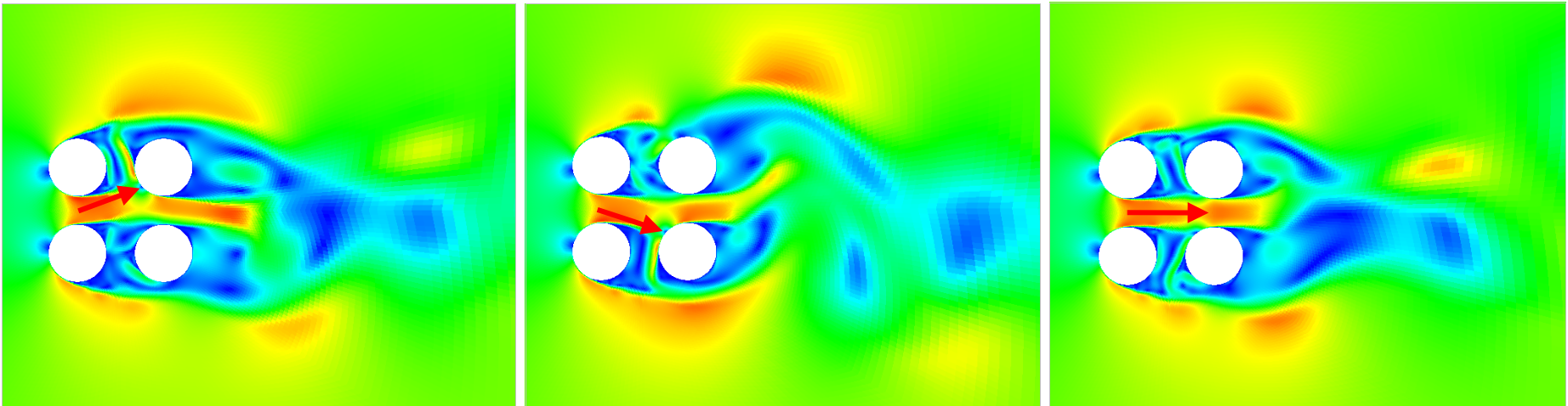

The wake patterns of the cylinders reveal the flow deflection with a mode change in figure 6, where the three modes (Mode 1, Mode 2, and Mode 3) are illustrated. The transition from one mode to another is non-periodic and unpredictable, which was also observed in the case of two side-by-side cylinders discussed by Afgan et al. [8]

3. 2. Staggered configuration

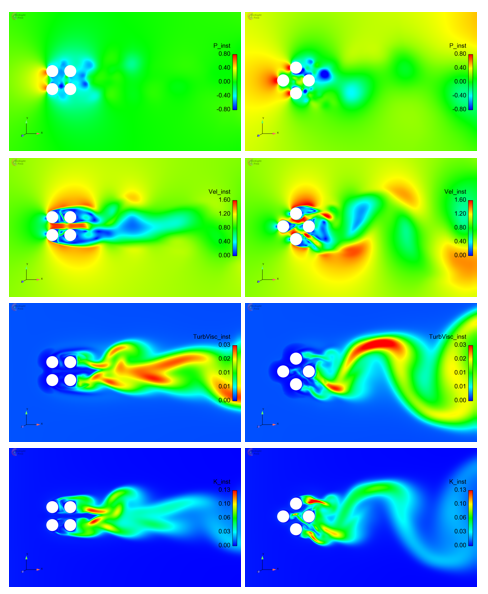

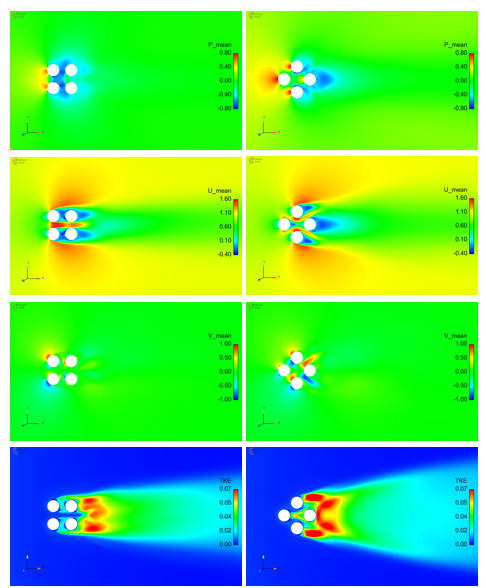

(a) in-line configuration, (b) staggered configuration.

The current staggered configuration of the four cylinders resulted from the rotation of the in-line four-cylinder by 45 degrees with the same spacing of P/D = 1.5. This arrangement places Cylinder 3 directly downstream of Cylinder 1 along the X-axis, with Cylinder 2 and Cylinder 4 positioned adjacent to each other along the Y-axis.

In comparison with the in-line four-cylinder configuration, the greater level of interference between the cylinders results in a more intricate pattern of behavior being observed.

Considering the rapid variations in direction and intensity of the incoming flow onto Cylinder 3, it can be inferred that the interaction between the vortices and the cylinder structure will lead to significant fluctuations in the pressure forces and overall load on the downstream cylinder. Compared with the four cylinders in an in-line configuration, the shear layers that separate from cylinder 1 are not able to extend sufficiently to encircle cylinder 3 located downstream due to the effect of cylinders 2 and 4 on the flow.

(a) in-line configuration, (b) staggered configuration.

4. Conclusion

A numerical study using the open-source and free software Code_Saturne was carried out by analyzing the dynamic behavior of an incompressible turbulent flow around four cylinders in a square in-line and staggered arrangement.

The resulting velocity and pressure fields, as well as the recirculation length of the flow, are presented and validated for the configuration of four cylinders in a square in-line arrangement with a center spacing of P/D = 1.5 and a Reynolds number equal to 3000. The mean velocity profiles for different positions in the wake region were plotted and analyzed, and the bi-stability phenomenon was detected.

For the case of four cylinders in a square arrangement with staggered configuration, a jet flow is observed, which is distinct from the regular gap flow, characterized by a narrow width and high velocity. Altering the wake shape can cause significant variations in the magnitude and direction of the jet flow, resulting in potential structural vibrations that must be considered in practical engineering applications.

Jet flow can induce destructive vibrations in a heat exchanger by creating fluid-structure interactions. This vibrational effect must be considered during design to prevent fatigue and potentially catastrophic failure. Mitigating these issues may involve reviewing the flow limits and exchanger geometry.

References

[1] Adobes, A., Jusserand, F., Benhamadouche, S., Kahil, Y., Belouah, S., Computation of Fluid Forces Acting on an Infinite Cylinder Submitted to a Single Phase Cross Flow. Proceedings of the ASME 2010 3rd Joint US-European Fluids Engineering Summer Meeting collocated with 8th International Conference on Nanochannels, Microchannels, and Minichannels. ASME 2010 7th International Symposium on Fluid-Structure Interactions, Flow-Sound Interactions, and Flow-Induced Vibration and Noise: Volume 3, Parts A and B. Montreal, Quebec, Canada. August 1–5, 2010. pp. 241-250. ASME. View Article

[2] Y. Kahil, "Simulation des grandes échelles d'écoulements turbulents autour de cylindres circulaires à un nombre de Reynolds sous critique," Ph.D. dissertation, Institut d'Alembert, Université Pierre et Marie Curie, Paris, France, 2011.

[3] Md. M. Alam, H. Sakamoto, and Y. Zhou, "Determination of flow configurations and fluid forces acting on two staggered circular cylinders of equal diameter in cross-flow," J. Fluids Struct., vol. 21, no. 4, pp. 363-394, 2005. View Article

[4] A. V. de Paula, L. A. M. Endres, and S. V. Möller, "Experimental study of the bistability in the wake behind three cylinders in triangular arrangement," J. Braz. Soc. Mech. Sci. Eng., vol. 35, no. 2, pp. 163-176, 2013. View Article

[5] G. Pouryoussefi, M. M, and A. M.A, "Experimental Investigation of Force Coefficients for Groups of Three and Four Circular Cylinders Subjected to a Cross-flow," Mech. Aerosp. Eng. J. Fluids Aerodyn., vol. 5, no. 1, pp. 87-95, 2009.

[6] K. Lam and L. Zou, "Experimental study and large eddy simulation for the turbulent flow around four cylinders in an in-line square configuration," Int. J. Heat Fluid Flow, vol. 30, no. 2, pp. 276-285, 2009. View Article

[7] L. Zou, Y. Lin, and H. Lu, "Flow Patterns and Force Characteristics of Laminar Flow Past Four Cylinders in Diamond Arrangement," J. Hydrodyn., vol. 23, no. 1, pp. 55-64, 2011. View Article

[8] I. Afgan, Y. Kahil, S. Benhamadouche, and P. Sagaut, "Large eddy simulation of the flow around single and two side-by-side cylinders at subcritical Reynolds numbers," Phys. Fluids, vol. 23, no. 7, p. 075101, 2011. View Article

[9] F. Tong, L. Cheng, and M. Zhao, "Numerical simulations of steady flow past two cylinders in staggered arrangements," J. Fluid Mech., vol. 765, pp. 114-149, 2015. View Article

[10] Z. Rahmani, Y. Kahil, and A. Benlefki, "Étude numérique d'écoulement turbulent autour de quatre cylindres en configuration carré," Recueil de mécanique. vol. 4, no. 2, pp. 359-73, 2020.

[11] C. Geuzaine and J. F. Remacle, "Gmsh: a three-dimensional finite element mesh generator with built-in pre- and post-processing facilities," Int. J. for Numerical Methods in Engineering 79(11), 1309-1331, 2009. View Article

[12] F. Archambeau, N. Méchitoua and M. Sakiz. "Code Saturne: A Finite Volume Code for the computation of turbulent incompressible flows - Industrial Applications," Int. J. on Finite Volumes, 1 (1), 2004.

[13] Computational Engineering International, Inc. (CEI EnSight Free) 2166 N. Salem Street, Suite 101, Apex, NC 27523 USA.