Volume 11 - Year 2024 - Pages 404-415

DOI: 10.11159/jffhmt.2024.040

Advanced Flow Control Innovations for Optimizing Wind and Water Turbine Performance: Toward Sustainable Energy Solutions

Dr. Surupa Shaw1,2,3, Edwin Javier Cortes1,2,3

1Department of Multidisciplinary Engineering

2TAMU Higher Education Center at McAllen

3Texas A&M University, CS, USA

surupashaw@tamu.edu; edwin.cortes@tamu.edu

Abstract - In recent years, the focus on improving wind and water turbine efficiency has intensified to meet the rising demand for sustainable energy. One promising avenue is the use of advanced flow control techniques to optimize aerodynamic performance. This paper investigates how these techniques, applied to wind and water turbines, can maximize energy capture, reduce drag, and mitigate turbulence-induced losses by manipulating airflow or water flow around turbine blades. It explores a range of passive and active methods, including vortex generators, boundary layer suction, and plasma actuators, assessing their effectiveness under varying conditions. The paper also addresses the practical challenges of implementing these techniques in turbine designs, considering factors such as cost, reliability, scalability, and their overall impact on turbine efficiency and lifecycle. Drawing from research and case studies, this paper provides a detailed review of the benefits and limitations of advanced flow control strategies and identifies opportunities for further development. Ultimately, it aims to advance turbine technology, accelerating progress toward more sustainable energy solutions.

Keywords: Flow Control, aerodynamics, Wind Turbine, Water Turbine, Efficiency, Passive Control, Active Control.

© Copyright 2024 Authors - This is an Open Access article published under the Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2024-04-04

Date Revised: 2024-09-18

Date Accepted: 2024-11-14

Date Published: 2024-11-22

1. Introduction

The technological advancements of the 21st century have driven a shift from fossil fuels to eco-friendly renewable energy sources, spurred by environmental concerns and the need for sustainable power. This transition seeks to not only reduce environmental damage but also establish renewable energy sources like hydro, solar, wind, and bioenergy, which offer cleaner and locally available alternatives. The Global Wind Energy Council (GWEC) reported a 10% increase in global wind energy capacity, with a projected growth rate of 9.2% over the next five years, underscoring the growing demand for renewable energy. Despite the increasing use of wind and water turbines, challenges remain in maximizing their aerodynamic performance, which directly affects efficiency and energy output. To address this, researchers have turned to advanced flow control techniques. Xu et al. [1] applied plasma flow control technology on the Savonius VAWT blade to stabilize flow separation, reduce disturbances, and optimize boundary layer dynamics, improving performance by altering pressure distribution. Akhter et al. [2] introduced a combination of active and passive control mechanisms, using blade sensors to analyze local conditions and passive geometries to stabilize pressure gradients. Similarly, Acarer [3] enhanced the peak lift-to-drag ratio of the DU12W262 airfoil through passive control methods, including suction-side allowances and trailing-edge slots, boosting the power coefficient of horizontal and vertical axis turbines by 3.2%. Further approaches have been explored, such as optimizing cycloidal water turbines, where individual blade control strategies maximize rotor power by adjusting tip speed ratios. Techniques like altering pitch and phase angles have also shown potential for improving turbine performance. For example, Hwang [4] amplified power generation in horizontal axis wind turbines by 4.2%, as demonstrated by Cooney [5]. These advancements demonstrate the promise of flow control techniques in enhancing turbine efficiency and addressing the growing demand for renewable energy sources.

Each flow control technique offers distinct advantages when applied to turbines, and selecting the most efficient system depends on the technology and environmental factors. Bay et al. [6] demonstrated a 10-15% increase in wind power plant efficiency by utilizing downwind rotors in their 2019 study. Other innovative approaches include non-traditional blade control systems, such as the modulated circulation technique employed by Wiratama [7], which adjusts velocity and pitch to optimize vertical axis hydrokinetic turbines. Gorle [8] found that this method improved efficiency as free-stream velocity increased. Moshfeghi et al. [9] focused on split-blade passive flow management, observing that separation on horizontal axis wind turbine blades—common in turbulent conditions—can be mitigated using vortex generators. Van Dam et al. [10] explored active load control methods like shape-changing airfoils and Active Flexible Walls, which not only extend the turbine's lifespan but also mitigate the effects of turbulent winds. Passive control methods, while cheaper and easier to implement, have shown to increase aerodynamic efficiency by reducing power loads and improving turbine performance, as noted by González-Salcedo [11]. However, active methods—though more effective—require extensive 2D and 3D simulations. For water turbines, research is less extensive, but Lekube et al. [12] demonstrated a notable 9.8% improvement in energy conversion by using a control scheme of Oscillating Water Column (OWC) sensors, flow controllers, and pressure sensors, increasing power generation by almost 1kW over a 5-minute period. These studies highlight the importance of selecting the appropriate flow control strategy to maximize turbine performance based on specific environmental conditions and operational requirements.A very interesting and relevant method used was made by Shourangiz-Haghighi et al. [13] who provided an overview of state-of-the-art methods using computational fluid dynamics (CFD) to optimize the shape of an airfoil with optimization algorithms, testing different materials and shapes of airfoils for wind turbine performance, since it can visualize flow fields as well as testing new designs.

This paper aims to investigate the potential of advanced flow control techniques for enhancing the aerodynamic performance of wind and water turbines. Utilizing fluid dynamics principles, researchers have developed innovative methods to manipulate air and water flow around turbine blades, optimizing efficiency and energy capture. The paper will explore the core principles of flow control and their application in turbine performance enhancement. It will examine both active techniques, such as vortex generators, plasma actuators, and synthetic jets, and passive methods, including aerodynamic shaping and surface coatings, to assess their effectiveness in improving turbine efficiency.

2. FUNDAMENTAL DESIGN & STRUCTURE OF WIND & WATER TURBINE

Wind and water turbines play a crucial role in harnessing renewable energy from natural resources. Each turbine's unique design is tailored to efficiently capture the kinetic energy of wind or flowing water, optimizing the process of converting these natural forces into usable electrical power.

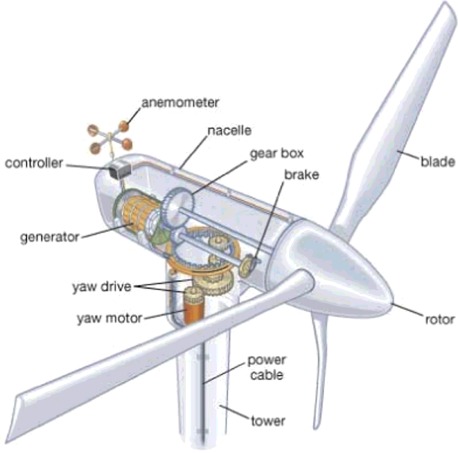

A wind turbine’s design includes several essential components. Central to this is the rotor, which features blades attached to a hub, crafted aerodynamically to efficiently harness wind energy. As the wind drives the rotor, its rotational energy is transmitted via a shaft to a generator located in the nacelle—a box structure positioned atop the turbine tower. The nacelle also houses the gearbox, engine, and control systems. The generator then converts the mechanical energy into electrical energy, which is transmitted through cables down the tower to the grid, as shown in Figure 1.

According to Hansen [14,15] and van der Tempel and Molenaar [16], the fundamental design of a wind turbine is aimed at efficiently capturing the kinetic energy of the wind and converting it into electrical power. The rotor comprises multiple blades attached to a central hub, which serves as the control system for the turbine. These blades have aerodynamic profiles specifically designed to enhance lift and reduce drag, ensuring effective wind energy capture. The wind drives the rotor's rotation, transforming kinetic energy into rotational motion. The rotor assembly is housed within the nacelle, which contains crucial components such as the gearbox, generator, and control systems, and is mounted on a tall tower. To optimize energy conversion and wind capture, the nacelle is positioned strategically. The generator converts the mechanical energy into electrical power, while the gearbox increases the rotor shaft's rotational speed to a level suitable for power generation. Additionally, control devices within the nacelle monitor wind conditions and adjust the blade orientation to maximize energy capture and ensure safe operation.

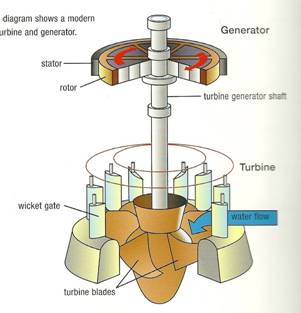

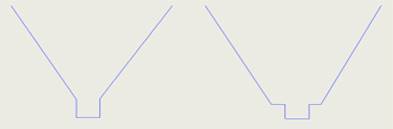

Water turbines are engineered to capture the kinetic energy of water flowing through rivers, streams, or ocean currents. Their fundamental design is similar to that of wind turbines but adapted for underwater use, featuring a rotor with blades suited for aquatic environments. Water turbines come in various types, including impulse turbines and reaction turbines. Impulse turbines harness the kinetic energy of flowing water to power their blades, whereas reaction turbines utilize both the kinetic and pressure energy of the water. As illustrated in Figure 2, the rotor of a water turbine is connected to a shaft that transmits rotational energy to a generator. Depending on their size and purpose, water turbines can be installed directly in natural water bodies or within engineered systems such as dams and hydroelectric facilities.

According to Van der Tempel and Molenaar [16], the essential component of a water turbine is a rotor assembly with blades tailored for underwater environments, similar in concept to wind turbines but specifically adapted for aquatic settings. Water turbines come in diverse designs, from small river turbines to large offshore systems, depending on their intended application and environment. Like wind turbines, the rotor assembly is connected to a shaft that transmits rotational energy to a generator. However, designing and constructing water turbines requires addressing the specific dynamics of water flow and the structural needs for underwater operation. Zanette et al. [17] present a design methodology for crossflow water turbines, emphasizing critical factors such as blade design, form, and pitch to optimize energy conversion. Furthermore, Sick et al. [18] examine the dynamic performance of water turbines, stressing the importance of stability and structural integrity under various flow conditions.

3. CHALLENGES – TABLE: COMPARISON OF WIND V/S WATER TURBINE

Examining the systems within wind and water turbines enables us to pinpoint factors that influence energy capture, flow dynamics, and structural resilience. This analysis sheds light on optimization opportunities, identifying specific design and control strategies that enhance overall functionality and adaptability to environmental challenges, ultimately driving advancements in renewable energy technology. A thorough analysis of these systems not only aids in refining turbine efficiency but also supports innovations that could reduce operational costs and extend turbine lifespan.

Table 1 provides a comparative analysis, highlighting both similarities and distinct differences. It details how each turbine type's components and operational principles are uniquely adapted to harness energy from their respective environments effectively.

Table 1: Comparison of wind v/s water turbine

|

Current challenges |

Wind turbine |

Water turbine |

|

Environmental impact |

· Local fauna may be impacted by wind plants, due to the large blades. [19] Saidur, R., · Visual impedance due to large components. |

· Installation-related regulations involve conformity to environmental impact. [20] McKenna, R.

|

|

Resource |

· Remote areas tend to be home to ideal wind settings. · Highly dependent on locations and wind patterns [21] Tasneem, Z. · Large amount of material to set up and transport. |

· Requires consistent water flow and certain velocity. [22] Nielsen, F.G |

|

Availability |

· Initial investment will be high. · Low win speeds decrease energy production. [23] Guerra, O.J. |

· Turbine efficiency and availability of water. · vulnerability to floods or droughts which influence the availability of water and the performance of turbines. [24] Konstantinidis, E.I. |

|

Efficiency |

· Production of energy decreases at low wind speeds: Reduced effectiveness when there is little wind. · Fatigue Loads affect control. [25] McKenna, R · Low wind creates low efficiency.

|

· Concerns of structural stability in dynamic water currents due to unstable waters. · Turbulence around the blades of turbines and the velocity of water flow affect efficiency. [26] Liu, X.,

|

|

Maintenance |

· Components at optimal performance and lifetime require regular maintenance. [27] Tchakoua, P. · Deterioration of moving parts as a result of continuous use and weather exposure

· Risk of strikes by lightning on towering wind turbines

|

· There is a chance of fouling and corrosion in submerged situations. · Obtaining and maintaining submerged turbine parts presents difficulties. [28] Yang, W.

|

4. ADVANCED FLOW CONTROL TECHNIQUES FOR OVERCOMING CHALLENGES

4.1. Wind turbines:

- Plasma flow control

Researchers and engineers have developed innovative flow control techniques to overcome the challenges wind and water turbines face in optimizing energy output and efficiency. For example, Guoqiang L [29] utilized plasma flow control technology to improve boundary layer dynamics, minimize flight disturbances, and stabilize flow separation in Savonius VAWT blades.

- Blade sensors

Similarly, blade sensors are employed in active control systems to assess local conditions, while geometric shaping is utilized in passive mechanisms to stabilize pressure gradients. These adjustments modify the pressure distribution, leading to enhanced performance. The modifications also address issues related to material degradation and blade deformation, reducing maintenance needs by slowing the deterioration of the blades and extending their lifespan.

- Yaw system regulation

The dynamic and turbulent nature of wind flows presents a challenge for operating wind turbines, often leading to mechanical stress and reduced performance. By adjusting yaw systems, turbines can optimize energy capture and mitigate aerodynamic loads. According to Kim [32], these adjustments can reduce fatigue by up to 40% and decrease extreme loads by up to 19% under severe wind conditions.

- Lidar technology, sonic sensor, Blade pitch angles

Blade pitch angles can be adjusted in real-time using advanced control algorithms, including cross-axis wind turbines and magnetic-based turbines, as demonstrated by Roga et al. [33]. Additionally, Shourangiz-Haghighi et al. [34] and Adekanbi [35] highlight that integrating sensor technologies such as Lidar, sonic sensors, predictive control systems, and collective pitch control—along with a tracker capable of functioning under both normal and abnormal conditions—enables turbines to swiftly adapt to changing wind conditions. This optimization enhances power output while minimizing structural wear and tear. By extending the operational lifespan of wind turbines and improving their efficiency and reliability, these methods contribute to the overall cost-effectiveness of wind power generation.

- Voltage support and frequency adjustment

Grid integration and stability, particularly regarding the variability of wind power supply, present additional challenges. By comparing wind and wave energy models, as described by Ringwood [36], both wind and water turbines can offer ancillary services to the grid, such as voltage support and frequency regulation, helping to maintain grid stability.

- Internal Model Control (IMC) and ultrasonic testing

Control solutions, such as integrated high/low-level controllers and Internal Model Control (IMC), bolster grid resilience by adjusting turbine capacity in response to grid frequency fluctuations. By optimizing rotor speed and blade pitch according to wind flow velocity, the power coefficient can be maximized, reducing the risk of grid instability and enhancing overall system reliability. Additionally, as demonstrated by Márquez, F.P.G [37], optimizing wind turbine performance through techniques like ultrasonic testing, acoustic emission, and strain measurements allows for comprehensive monitoring of multiple turbines. This not only improves blade maintenance and fault detection but also reduces wake effects, boosting the efficiency and economic viability of wind energy generation.

4.2. Water turbines:

- Speed regulations, electronic load Controller ELC, and flow control machines

The variable nature of water flow presents a significant challenge for water turbines, as it can greatly impact their efficiency and performance. Parish [38] suggests that incorporating speed regulation and flow control mechanisms, along with reducing electrical power input by integrating an Electronic Load Controller (ELC), allows turbines to dynamically respond to fluctuations in water flow. These adaptations help maximize energy extraction across a range of operating conditions, improving overall turbine performance.

- Blade pitch angle adjustment

Turbines with advanced control algorithms can make real-time adjustments to guide vane locations or blade pitch angles to ensure maximal energy capture and minimize performance losses caused by undesirable operating conditions. Because of their increased adaptability, water turbine systems are more resilient and can continue to function well even when flow rates fluctuate.

- PID controls and MSC control loops

Sahraei et al. [39] demonstrate improved grid stability and integration, particularly in micro-hydro power plants. Sami et al. [40] propose control strategies such as PID controls and MSC control loops, enabling micro-hydro systems to actively contribute to grid stability, much like synchronous generators. These strategies allow for the release or absorption of speed or torque based on power imbalances and include synthetic inertia frequency support. These control solutions, combined with fast frequency reserves, enhance grid resilience by adjusting turbine output in response to grid frequency variations, thereby reducing the risk of instability and improving overall system durability.

- Axial flow water turbines, inclined axis, and rigid mooring

Plant optimization and grid interaction are key considerations in optimizing water turbine systems, extending beyond the performance of individual units. Advanced flow control systems within a hydroelectric structure enable the coordinated operation of multiple turbines, maximizing overall energy capture while minimizing negative effects such as cavitation and structural wear. Research by Khan et al. [41] demonstrates how factors like axial flow water turbines, inclined axes, and rigid mooring can significantly influence system performance.

- Blade pitch angles, shaft inclinations, or guide vane placements in real-time

Real-time adjustments to blade pitch angles, shaft inclinations, or guide vane positions can optimize energy capture by up to 30% through mechanical control across various flow conditions. This adaptability ensures consistent water turbine operation even with fluctuating water flow rates, while also enhancing efficiency. Additionally, certain designs, like the Darrieus turbine, outperform others; for instance, the Darrieus turbine achieves 55% better performance compared to the Savonius turbine in a 5kVA system, as demonstrated by Kiho S [42].

5. COMPARATIVE ANALYSIS OF FLOW CONTROL METHODS

Optimizing energy capture and overall productivity in wind and water turbines hinges on their aerodynamic performance. Table 2 outlines and analyzes various flow control methods, showcasing their benefits and impacts when applied to turbines to enhance aerodynamic efficiency.

Table 2 Comparative analysis of flow control methods

|

Flow Control Methods |

Wind Turbines |

Water Turbines |

|

Plasma flow & passive control techniques |

- Optimized boundary layer dynamics - Decreased flow disturbances in VAWT blades - Stabilizing flow separation - Active control systems with blade sensors |

- Flow control mechanisms - Speed regulations - Electronic load controllers (ELCs) - Micro-hydro systems |

|

Yaw systems control |

- Refining energy capture - Lowering aerodynamic loads - Real-time blade pitch angle change |

- Multi-Step Control (MSC) loops - Proportional-Integral-Derivative (PID) controllers |

|

Sensors & program controls |

- Sonic and Lidar sensors combined with predictive control - Grid integration control - Collective pitch control |

- Real-time adjustments to guide vane locations or blade pitch angles - Varying turbine's rotational speed |

|

Monitoring techniques |

- Acoustic emission measurements - Ultrasonic testing - Minimize wake effects - Early problem diagnosis |

- Optimization of individual units and plants - Real-time modifications to shaft inclinations or guide vane placements - Modern turbine designs like Darrieus turbine - Individual blade control - Direct power control |

6. EMERGING TRENDS

The effectiveness of wind and water turbine innovations has been demonstrated in several studies, but there is a clear need for more long-term field testing. Much of the available data stems from short-term or small-scale experiments that fail to capture the complex dynamics of real-world environments.

The recent advancements in flow-control devices for enhancing wind turbine performance is focusing on several emerging trends aimed at improving aerodynamic efficiency and energy output. Active flow control techniques, such as synthetic jets and plasma actuators, are being developed to dynamically manipulate airflow over turbine blades, delaying flow separation and augmenting lift in response to variable wind conditions. Concurrently, the optimization of passive flow control devices, including vortex generators and trailing-edge flaps, is gaining momentum, enhancing stall characteristics and extending operational ranges without external power input. Additionally, the integration of computational fluid dynamics (CFD) with advanced machine learning algorithms is facilitating the development of predictive models that leverage real-time data to optimize flow-control strategies, significantly improving performance metrics. There is also a notable interest in biomimetic designs that draw inspiration from natural systems to achieve efficient airflow management, aiming to minimize drag and maximize lift. Collectively, these trends are setting the stage for more efficient, resilient, and adaptive wind turbine technologies, contributing to substantial advancements in renewable energy systems. Future research should prioritize large-scale, longitudinal studies that monitor turbine performance across a variety of climates and operational conditions. This would provide a more comprehensive understanding of the trade-offs between efficiency, cost, and system durability. The future of renewable energy will depend on interdisciplinary collaboration between material scientists, control engineers, and environmental researchers to develop more resilient, adaptable, and cost-effective turbine systems.

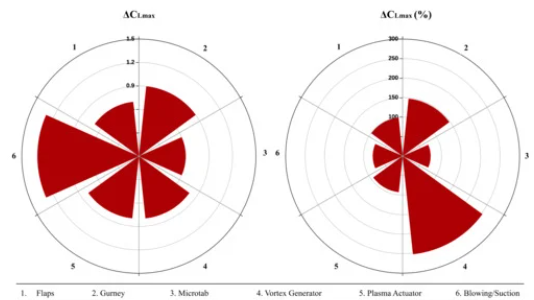

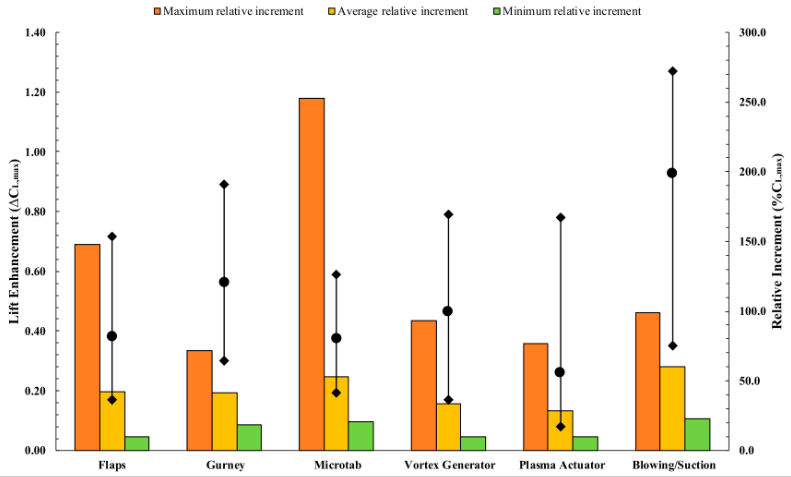

Akhter et al. [43] demonstrate that emerging wind turbine devices like flaps, vortex generators, microtabs, and plasma actuators significantly reduce turbulence and load fluctuations, boosting efficiency. These technologies also lower maintenance costs and extend blade lifespans, addressing challenges posed by larger, more fatigue-prone turbines. Figure 3 demonstrates lift enhancements (ΔCLmax) ranging from 0.6 to 1.3, with relative improvements (%CLmax) between 72% and 253%. Most devices have successfully completed field testing (TRL 7) and are progressing toward full commercialization (TRL 9). Flaps and vortex generators, already widely implemented, enhance annual energy production (AEP) by 3–5% in multi-MW wind turbines.

Figure 4 compares the aerodynamic performance of various flow-control devices, highlighting their effectiveness in lift enhancement through two key metrics: ΔCLmax (maximum lift coefficient improvement) and %CLmax (relative lift enhancement percentage). ΔCLmax measures the increase in maximum lift, while %CLmax quantifies its percentage improvement. According to wind turbine studies, the co-flow jet mechanism (blowing-suction) achieves the highest ΔCLmax, indicating the greatest lift enhancement. Blowing-suction jets and Gurney flaps exhibit the best average controllability in terms of lift. Vortex generators, plasma actuators, and blowing-suction control are particularly effective in extending stall at high angles of attack (AOAs), though their efficiency decreases at lower AOAs, except for continuous blowing and co-flow jets, which maintain performance across a wider AOA range. These results suggest that co-flow jets offer superior lift control, especially in challenging flow conditions.

Acarer [44] conducted wind tunnel tests and numerical simulations to evaluate various passive flow control techniques, such as vortex generators and surface modifications, on the DU12W262 airfoil, that significantly enhanced the peak lift-to-drag ratio, delayed flow separation, and improved lift characteristics, benefiting the aerodynamic performance of both horizontal and vertical axis wind turbines, leading to more efficient designs. This enhancement can lead to better energy capture and operational efficiency in renewable energy applications.

Current research in flow-control devices for water-turbine performance is focused on several challenging emerging trends that aim to enhance efficiency and energy production. One significant area of interest is the development of smart materials, which can adaptively change their properties in response to varying flow conditions. These materials can optimize performance in real-time, ensuring that turbines operate efficiently under different circumstances. Another trend is the integration of machine learning algorithms to optimize flow control strategies based on historical and operational data. By leveraging data analytics, researchers can develop predictive models that enhance decision-making processes related to flow management, improving overall turbine performance. The exploration of micro-scale flow control devices is also gaining traction. These devices can manipulate flow at a granular level, providing precise control over fluid dynamics and leading to increased turbine efficiency. Additionally, researchers are investigating biomimetic designs, drawing inspiration from natural systems to create innovative flow-control solutions. These designs aim to enhance energy extraction while minimizing environmental impacts, thereby promoting sustainability in hydro systems. Together, these emerging trends represent a significant shift in the approach to flow control in water turbines, promising advancements in renewable energy technology.

Popescu et al. [45] investigated flow control techniques in Banki turbines using computational fluid dynamics (CFD) simulations. The study aimed to optimize turbine performance by enhancing flow distribution and minimizing turbulence. The results demonstrated improved efficiency and energy conversion through optimized flow control strategies, leading to better overall turbine performance.

Adhikari et al. [46] used computational fluid dynamics (CFD) to analyze part-load flow control in crossflow turbines. A slider mechanism reduced the entry flow area, maintaining high efficiency down to 40% load, with constant shaft speed, simplifying power electronics. These turbines are vital for remote power in developing countries.

Dhakal et al. [47] performed comparative studies on cylindrical and conical vortex chambers using CFD simulations and experimental data. All geometric parameters were kept constant, except for the outlet tube geometry. The modifications, shown in Figure 5, were analysed for performance effects. As the basin design shifts from cylindrical to conical, velocity increases with the cone angle, resulting in higher power production. The top diameter of the basin was reported to be 600 mm, with a height of 850 mm. Both numerical and experimental studies indicated that the output power and efficiency were highest in the conical basin. Experimentally, the maximum efficiency for the cylindrical basin was 27.74%, whereas the conical basin achieved a significantly greater efficiency of 36.84%.

Wang et al. [48] analyses the hazards of vortex rope in turbine draft tubes and methods for suppression. Vortex formation during partial load conditions reduces turbine stability, efficiency, and operating life, causing pressure pulsation, cavitation, and vibrations that may lead to serious damage. Passive flow control methods, such as altering the draft tube's geometry and adding fins or baffles, help suppress vortex development and pressure fluctuations. Active flow control techniques, including air and water injection, adjust flow velocity and pressure to reduce cavitation and vortex strength. Optimal air injection (about 2% of liquid flow) is more effective than water injection for improving turbine performance.

Nishi et al. [49] conducted a study on water vortex hydropower technology using both CFD and experimental methods to simulate multiphase flow with a turbine runner in a water vortex. The results demonstrated a strong correlation between computational and experimental data. Kueh et al. [50] also conducted experimental research on turbine runners, showing that curved blades, especially those curved in the vertical plane at the exit, are more efficient in improving turbine performance.

Emerging trends in wind and water turbine performance enhancement through flow-control devices focus on real-time adaptability and increased efficiency. One of the key challenges for urban Vertical Axis Wind Turbines (VAWTs) is their performance in low wind speed conditions, which are common in urban environments. Bello et al. [51] emphasized critical challenges for future research and development, particularly focusing on economic viability and the ability to self-start in very low wind speeds, which remains a significant barrier. Rashid's [52] simulation models wind energy integration, focusing on wind speed variations, power generation, consumption, and control systems. It analyzes fluctuations in power generation (88.89%) and consumption, with the control system minimizing power differences to ensure stability despite wind speed changes. Firoozi et al. [53] discusses the development of adaptive, smart wind turbine blades that dynamically adjust to changing wind conditions. They suggest that integrating smart materials, MEMS, AI, and machine learning can enhance performance, reduce stress, improve aerodynamics, and lead to more efficient designs and faster development cycles. Samaei et al. [54] highlight the pivotal role of AI in enhancing coastal hydro energy systems. AI's predictive and adaptive capabilities improve turbine efficiency, reliability, and sustainability by forecasting tidal and wave patterns and adjusting operations in real-time. This integration advances smart energy solutions aligned with global sustainability goals. Zakir et al. [55] introduce the E-115 wind turbine model, highlighting its cost-effectiveness and economic advantages through metrics like LCOE, NPV, and IRR. The study emphasizes the model’s structural stability, potential for reducing greenhouse gas emissions by 97.26%, and its role in advancing sustainable energy and eco-conscious development.

Active methods like synthetic jets and plasma actuators dynamically adjust airflow for wind turbines, while smart materials and biomimetic designs optimize water turbine performance. Machine learning models and micro-scale control devices further drive precision in fluid dynamics, improving both energy capture and system longevity. These innovations, backed by computational simulations and experimental studies, are poised to reduce operational costs, enhance power output, and extend the life of turbine systems, advancing renewable energy technologies globally.

7. CONCLUSION: FUTURE DIRECTIONS AND POTENTIAL INNOVATIONS

Despite significant advancements in flow control systems for wind and water turbines, there remain numerous opportunities for further research and development. First, additional optimization and enhancement of existing flow control techniques are needed to improve their efficiency and reliability across various operating environments and conditions. Furthermore, future research should focus on integrating advanced flow management methods with cutting-edge technologies such as artificial intelligence, machine learning, and advanced materials. These innovations could lead to the development of autonomous turbine control systems capable of real-time optimization and adaptation.

Extensive field testing and validation of advanced flow control methods in actual turbine installations are essential to assess their long-term reliability and performance. Collaboration among researchers, industry stakeholders, and policymakers will be crucial for accelerating the transition to a sustainable energy future and promoting the deployment of these technologies. Ongoing innovation in flow control systems is key to maximizing the potential of wind and water turbines as reliable, efficient, and eco-friendly energy sources. Researchers have effectively addressed challenges such as aerodynamic limitations and structural stresses through creative solutions like plasma flow control, passive geometric shaping, active blade sensors, and real-time control algorithms.

For wind turbines, reducing turbulence-induced losses and enhancing energy capture efficiency are achieved through various control methods. Passive controls directly influence turbine materials, while active controls, although more costly, offer improved efficiency. Techniques like sensor-based predictive control, real-time blade pitch adjustments, and yaw system modifications enable rapid responses to changing wind conditions, boosting overall efficiency. Similarly, water turbines benefit from advanced flow control devices, including flow control machines and innovative designs. Modern control algorithms and multi-turbine operation strategies allow these turbines to maximize energy extraction, adapt dynamically to varying flow rates, and support grid stability effectively.

References

[1] Xu, W., Li, C.C., Huang, S.X. and Wang, Y., 2022. Aerodynamic performance improvement analysis of Savonius vertical axis wind turbine utilizing plasma excitation flow control. Energy, 239, p.122133.

View Article

[2] Akhter, M.Z. and Omar, F.K., 2021. Review of flow-control devices for wind-turbine performance enhancement. Energies, 14(5), p.1268.

View Article

[3] Acarer, S., 2020. Peak lift-to-drag ratio enhancement of the DU12W262 airfoil by passive flow control and its impact on horizontal and vertical axis wind turbines. Energy, 201, p.117659.

View Article

[4] Hwang, I.S., Lee, Y.H. and Kim, S.J., 2009. Optimization of cycloidal water turbine and the performance improvement by individual blade control. Applied Energy, 86(9), pp.1532-1540.

View Article

[5] Cooney, J.A., 2014. Increasing power generation in horizontal axis wind turbines using optimized flow control (Doctoral dissertation, University of Notre Dame).

View Article

[6] Bay, C.J., Annoni, J., Martínez-Tossas, L.A., Pao, L.Y. and Johnson, K.E., 2019, July. Flow control leveraging downwind rotors for improved wind power plant operation. In 2019 American Control Conference (ACC) (pp. 2843-2848). IEEE.

View Article

[7] Wiratama, I.K., 2012. Aerodynamic design of wind turbine blades utilizing nonconventional control systems (Doctoral dissertation, Northumbria University).

[8] Gorle, J.M.R., Chatellier, L., Pons, F. and Ba, M., 2019. Modulated circulation control around the blades of a vertical axis hydrokinetic turbine for flow control and improved performance. Renewable and Sustainable Energy Reviews, 105, pp.363-377.

View Article

[9] Moshfeghi, M., Shams, S., & Hur, N. (2017, May 2). Aerodynamic performance enhancement analysis of horizontal axis wind turbines using a passive flow control method via split blade. Journal of Wind Engineering and Industrial Aerodynamics, 167, pp.148-152.

View Article

[10] Van Dam, C.P., Berg, D.E. and Johnson, S.J., 2008. Active load control techniques for wind turbines (No. SAND2008-4809). Sandia National Laboratories (SNL), Albuquerque, NM, and Livermore, CA (United States).

[11] González-Salcedo, Á., Croce, A., Arce León, C., Nayeri, C.N., Baldacchino, D., Vimalakanthan, K. and Barlas, T., 2020. Blade design with passive flow control technologies. Handbook of Wind Energy Aerodynamics, pp.1-57.

View Article

[12] Lekube, J., Garrido, A.J., Garrido, I., Otaola, E. and Maseda, J., 2018. Flow control in wells turbines for harnessing maximum wave power. Sensors, 18(2), p.535.

View Article

[13] Shourangiz-Haghighi, A., Haghnegahdar, M.A., Wang, L., Mussetta, M., Kolios, A. and Lander, M., 2020. State-of-the-art in the optimization of wind turbine performance using CFD. Archives of Computational Methods in Engineering, 27, pp.413-431.

View Article

[14] Hansen, M.O., 2000. Aerodynamics of wind turbines: rotors, loads and structure (Vol. 17). Earthscan.

[15] Hansen, M., 2015. Aerodynamics of wind turbines. Routledge.

View Article

[16] van der Tempel, J. and Molenaar, D.P., 2002. Wind turbine structural dynamics-a review of the principles for modern power generation, onshore and offshore. Wind engineering, 26(4), pp.211-222.

View Article

[17] Zanette, J., Imbault, D. and Tourabi, A., 2010. A design methodology for cross-flow water turbines. Renewable Energy, 35(5), pp.997-1009.

View Article

[18] Sick, M., Michler, W., Weiss, T. and Keck, H., 2009. Recent developments in the dynamic analysis of water turbines.

View Article

[19] Saidur, R., Rahim, N.A., Islam, M.R. and Solangi, K.H., 2011. Environmental impact of wind energy. Renewable and sustainable energy reviews, 15(5), pp.2423-2430.

View Article<

[20] McKenna, R., vd Leye, P.O. and Fichtner, W., 2016. Key challenges and prospects for large wind turbines. Renewable and Sustainable Energy Reviews, 53, pp.1212-1221.

View Article

[21] Tasneem, Z., Al Noman, A., Das, S.K., Saha, D.K., Islam, M.R., Ali, M.F., Badal, M.F.R., Ahamed, M.H., Moyeen, S.I. and Alam, F., 2020. An analytical review on the evaluation of wind resource and wind turbine for urban application: Prospect and challenges. Developments in the Built Environment, 4, p.100033.

View Article

[22] Nielsen, F.G., 2022. Perspectives and challenges related to offshore wind turbines in deep water. Energies, 15(8), p.2844.

View Article

[23] Guerra, O.J. and Reklaitis, G.V., 2018. Advances and challenges in water management within energy systems. Renewable and Sustainable Energy Reviews, 82, pp.4009-4019

View Article

[24] Konstantinidis, E.I. and Botsaris, P.N., 2016, November. Wind turbines: current status, obstacles, trends, and technologies. In IOP conference series: materials science and engineering (Vol. 161, No. 1, p. 012079). IOP Publishing.

View Article

[25] McKenna, R., vd Leye, P.O. and Fichtner, W., 2016. Key challenges and prospects for large wind turbines. Renewable and Sustainable Energy Reviews, 53, pp.1212-1221.

View Article

[26] Liu, X., Luo, Y., Karney, B.W. and Wang, W., 2015. A selected literature review of efficiency improvements in hydraulic turbines. Renewable and Sustainable Energy Reviews, 51, pp.18-28.

View Article

[27] Tchakoua, P., Wamkeue, R., Ouhrouche, M., Slaoui-Hasnaoui, F., Tameghe, T.A. and Ekemb, G., 2014. Wind turbine condition monitoring: State-of-the-art review, new trends, and future challenges. Energies, 7(4), pp.2595-2630.

View Article

[28] Yang, W., Tavner, P.J., Crabtree, C.J., Feng, Y. and Qiu, Y., 2014. Wind turbine condition monitoring: technical and commercial challenges. Wind energy, 17(5), pp.673-693.

View Article

[29] Guoqiang, L., Weiguo, Z., Yubiao, J. and Pengyu, Y., 2019. Experimental investigation of dynamic stall flow control for wind turbine airfoils using a plasma actuator. Energy, 185, pp.90-101.

View Article

[30] Bianchi, F.D., De Battista, H. and Mantz, R.J., 2007. Wind turbine control systems: principles, modeling and gain scheduling design (Vol. 19). London: Springer.

View Article

[31] Spilsbury and Spilsbury (2008). Diagram of the hydroelectric turbine.

[32] Kim, M.G. and Dalhoff, P.H., 2014, June. Yaw Systems for wind turbines-Overview of concepts, current challenges, and design methods. In Journal of Physics: Conference Series (Vol. 524, No. 1, p. 012086). IOP Publishing.

View Article

[33] Roga, S., Bardhan, S., Kumar, Y. and Dubey, S.K., 2022. Recent technology and challenges of wind energy generation: A review. Sustainable Energy Technologies and Assessments, 52, p.102239.

View Article

[34] Shourangiz-Haghighi, A., Diazd, M., Zhang, Y., Li, J., Yuan, Y., Faraji, R., Ding, L. and Guerrero, J.M., 2020. Developing more efficient wind turbines: A survey of control challenges and opportunities. IEEE Industrial Electronics Magazine, 14(4), pp.53-64.

View Article

[35] Adekanbi, M.L., 2021. Optimization and digitization of wind farms using internet of things: A review. International Journal of Energy Research, 45(11), pp.15832-15838.

View Article

[36] Ringwood, J.V. and Simani, S., 2015. Overview of modeling and control strategies for wind turbines and wave energy devices: Comparisons and contrasts. Annual Reviews in Control, 40, pp.27-49.

View Article

[37] Márquez, F.P.G., Tobias, A.M., Pérez, J.M.P. and Papaelias, M., 2012. Condition monitoring of wind turbines: Techniques and methods. Renewable energy, 46, pp.169-178.

View Article

[38] Paish, O., 2002. Small hydro power: technology and current status. Renewable and sustainable energy reviews, 6(6), pp.537-556.

View Article

[39] Sahraei, M.H., McCalden, D., Hughes, R. and Ricardez-Sandoval, L.A., 2014. A survey on current advanced IGCC power plant technologies, sensors, and control systems. Fuel, 137, pp.245-259.

View Article

[40] Sami, I., Ullah, N., Muyeen, S.M., Techato, K., Chowdhury, M.S. and Ro, J.S., 2020. Control methods for standalone and grid-connected micro-hydro power plants with synthetic inertia frequency support: A comprehensive review. IEEE Access, 8, pp.176313-176329.

View Article

[41] Khan, M.J., Iqbal, M.T. and Quaicoe, J.E., 2008. River current energy conversion systems: Progress, prospects, and challenges. Renewable and sustainable energy reviews, 12(8), pp.2177-2193.

View Article

[42] Kiho S, Shiono M, Suzuki K. The power generation from tidal currents by Darrieus turbines. In: Proceedings of the World Renewable Energy Congress, vol. 2. Denver, Colorado, USA; 1996. p. 1242-5.

View Article

[43] Akhter, M.Z. and Omar, F.K., 2021. Review of flow-control devices for wind-turbine performance enhancement. Energies, 14(5), p.1268.

View Article

[44] Acarer, S., 2020. Peak lift-to-drag ratio enhancement of the DU12W262 airfoil by passive flow control and its impact on horizontal and vertical axis wind turbines. Energy, 201, p.117659.

View Article

[45] Popescu, D., Popescu, C. and Dragomirescu, A., 2017. Flow control in Banki turbines. Energy Procedia, 136, pp.424-429.

View Article

[46] Adhikari, R.C. and Wood, D.H., 2018. Computational analysis of part-load flow control for crossflow hydro-turbines. Energy for sustainable development, 45, pp.38-45.

View Article

[47] Dhakal, S., Timilsina, A.B., Dhakal, R., Fuyal, D., Bajracharya, T.R., Pandit, H.P., Amatya, N. and Nakarmi, A.M., 2015. Comparison of cylindrical and conical basins with optimum position of runner: Gravitational water vortex power plant. Renewable and Sustainable Energy Reviews, 48, pp.662-669.

View Article

[48] Wang, L., Cui, J., Shu, L., Jiang, D., Xiang, C., Li, L. and Zhou, P., 2022. Research on the vortex rope control techniques in draft tube of Francis turbines. Energies, 15(24), p.9280.

View Article

[49] Nishi, Y. and Inagaki, T., 2017. Performance and flow field of a gravitation vortex type water turbine. International Journal of Rotating Machinery, 2017(1), p.2610508.

View Article

[50] Kueh, T.C., Beh, S.L., Rilling, D. and Ooi, Y., 2014. Numerical analysis of water vortex formation for the water vortex power plant. International Journal of Innovation, Management and Technology, 5(2), p.111.

[51] Bello, S.F., Lawal, R.O., Ige, O.B. and Adebayo, S.A., 2024. Optimizing vertical axis wind turbines for urban environments: Overcoming design challenges and maximizing efficiency in low-wind conditions. GSC Advanced Research and Reviews, 21(1), pp.246-256.

View Article

[52] Rashid, S.M., 2024. Employing advanced control, energy storage, and renewable technologies to enhance power system stability. Energy Reports, 11, pp.3202-3223.

View Article

[53] Firoozi, A.A., Hejazi, F. and Firoozi, A.A., 2024. Advancing Wind Energy Efficiency: A Systematic Review of Aerodynamic Optimization in Wind Turbine Blade Design. Energies, 17(12), p.2919.

View Article

[54] Samaei, S.R. and Ghahfarrokhi, M.A., 2023. Optimizing Coastal Hydro Turbines Integrating Artificial Intelligence for Sustainable Energy Conversion. In 2th International Conference on Creative achievements of architecture, urban planning, civil engineering and environment in the sustainable development of the Middle East.

[55] Zakir, M.N., Abasin, A.R., Irshad, A.S., Elias, S., Yona, A. and Senjyu, T., 2024. Practical Wind Turbine Selection: A Multicriterion Decision Analysis for Sustainable Energy Infrastructure. Practice Periodical on Structural Design and Construction, 29(3), p.04024028.

View Article

[1] Xu, W., Li, C.C., Huang, S.X. and Wang, Y., 2022. Aerodynamic performance improvement analysis of Savonius vertical axis wind turbine utilizing plasma excitation flow control. Energy, 239, p.122133. View Article

[2] Akhter, M.Z. and Omar, F.K., 2021. Review of flow-control devices for wind-turbine performance enhancement. Energies, 14(5), p.1268. View Article

[3] Acarer, S., 2020. Peak lift-to-drag ratio enhancement of the DU12W262 airfoil by passive flow control and its impact on horizontal and vertical axis wind turbines. Energy, 201, p.117659. View Article

[4] Hwang, I.S., Lee, Y.H. and Kim, S.J., 2009. Optimization of cycloidal water turbine and the performance improvement by individual blade control. Applied Energy, 86(9), pp.1532-1540. View Article

[5] Cooney, J.A., 2014. Increasing power generation in horizontal axis wind turbines using optimized flow control (Doctoral dissertation, University of Notre Dame). View Article

[6] Bay, C.J., Annoni, J., Martínez-Tossas, L.A., Pao, L.Y. and Johnson, K.E., 2019, July. Flow control leveraging downwind rotors for improved wind power plant operation. In 2019 American Control Conference (ACC) (pp. 2843-2848). IEEE. View Article

[7] Wiratama, I.K., 2012. Aerodynamic design of wind turbine blades utilizing nonconventional control systems (Doctoral dissertation, Northumbria University).

[8] Gorle, J.M.R., Chatellier, L., Pons, F. and Ba, M., 2019. Modulated circulation control around the blades of a vertical axis hydrokinetic turbine for flow control and improved performance. Renewable and Sustainable Energy Reviews, 105, pp.363-377. View Article

[9] Moshfeghi, M., Shams, S., & Hur, N. (2017, May 2). Aerodynamic performance enhancement analysis of horizontal axis wind turbines using a passive flow control method via split blade. Journal of Wind Engineering and Industrial Aerodynamics, 167, pp.148-152. View Article

[10] Van Dam, C.P., Berg, D.E. and Johnson, S.J., 2008. Active load control techniques for wind turbines (No. SAND2008-4809). Sandia National Laboratories (SNL), Albuquerque, NM, and Livermore, CA (United States).

[11] González-Salcedo, Á., Croce, A., Arce León, C., Nayeri, C.N., Baldacchino, D., Vimalakanthan, K. and Barlas, T., 2020. Blade design with passive flow control technologies. Handbook of Wind Energy Aerodynamics, pp.1-57. View Article

[12] Lekube, J., Garrido, A.J., Garrido, I., Otaola, E. and Maseda, J., 2018. Flow control in wells turbines for harnessing maximum wave power. Sensors, 18(2), p.535. View Article

[13] Shourangiz-Haghighi, A., Haghnegahdar, M.A., Wang, L., Mussetta, M., Kolios, A. and Lander, M., 2020. State-of-the-art in the optimization of wind turbine performance using CFD. Archives of Computational Methods in Engineering, 27, pp.413-431. View Article

[14] Hansen, M.O., 2000. Aerodynamics of wind turbines: rotors, loads and structure (Vol. 17). Earthscan.

[15] Hansen, M., 2015. Aerodynamics of wind turbines. Routledge. View Article

[16] van der Tempel, J. and Molenaar, D.P., 2002. Wind turbine structural dynamics-a review of the principles for modern power generation, onshore and offshore. Wind engineering, 26(4), pp.211-222. View Article

[17] Zanette, J., Imbault, D. and Tourabi, A., 2010. A design methodology for cross-flow water turbines. Renewable Energy, 35(5), pp.997-1009. View Article

[18] Sick, M., Michler, W., Weiss, T. and Keck, H., 2009. Recent developments in the dynamic analysis of water turbines. View Article

[19] Saidur, R., Rahim, N.A., Islam, M.R. and Solangi, K.H., 2011. Environmental impact of wind energy. Renewable and sustainable energy reviews, 15(5), pp.2423-2430. View Article<

[20] McKenna, R., vd Leye, P.O. and Fichtner, W., 2016. Key challenges and prospects for large wind turbines. Renewable and Sustainable Energy Reviews, 53, pp.1212-1221. View Article

[21] Tasneem, Z., Al Noman, A., Das, S.K., Saha, D.K., Islam, M.R., Ali, M.F., Badal, M.F.R., Ahamed, M.H., Moyeen, S.I. and Alam, F., 2020. An analytical review on the evaluation of wind resource and wind turbine for urban application: Prospect and challenges. Developments in the Built Environment, 4, p.100033. View Article

[22] Nielsen, F.G., 2022. Perspectives and challenges related to offshore wind turbines in deep water. Energies, 15(8), p.2844. View Article

[23] Guerra, O.J. and Reklaitis, G.V., 2018. Advances and challenges in water management within energy systems. Renewable and Sustainable Energy Reviews, 82, pp.4009-4019 View Article

[24] Konstantinidis, E.I. and Botsaris, P.N., 2016, November. Wind turbines: current status, obstacles, trends, and technologies. In IOP conference series: materials science and engineering (Vol. 161, No. 1, p. 012079). IOP Publishing. View Article

[25] McKenna, R., vd Leye, P.O. and Fichtner, W., 2016. Key challenges and prospects for large wind turbines. Renewable and Sustainable Energy Reviews, 53, pp.1212-1221. View Article

[26] Liu, X., Luo, Y., Karney, B.W. and Wang, W., 2015. A selected literature review of efficiency improvements in hydraulic turbines. Renewable and Sustainable Energy Reviews, 51, pp.18-28. View Article

[27] Tchakoua, P., Wamkeue, R., Ouhrouche, M., Slaoui-Hasnaoui, F., Tameghe, T.A. and Ekemb, G., 2014. Wind turbine condition monitoring: State-of-the-art review, new trends, and future challenges. Energies, 7(4), pp.2595-2630. View Article

[28] Yang, W., Tavner, P.J., Crabtree, C.J., Feng, Y. and Qiu, Y., 2014. Wind turbine condition monitoring: technical and commercial challenges. Wind energy, 17(5), pp.673-693. View Article

[29] Guoqiang, L., Weiguo, Z., Yubiao, J. and Pengyu, Y., 2019. Experimental investigation of dynamic stall flow control for wind turbine airfoils using a plasma actuator. Energy, 185, pp.90-101. View Article

[30] Bianchi, F.D., De Battista, H. and Mantz, R.J., 2007. Wind turbine control systems: principles, modeling and gain scheduling design (Vol. 19). London: Springer. View Article

[31] Spilsbury and Spilsbury (2008). Diagram of the hydroelectric turbine.

[32] Kim, M.G. and Dalhoff, P.H., 2014, June. Yaw Systems for wind turbines-Overview of concepts, current challenges, and design methods. In Journal of Physics: Conference Series (Vol. 524, No. 1, p. 012086). IOP Publishing. View Article

[33] Roga, S., Bardhan, S., Kumar, Y. and Dubey, S.K., 2022. Recent technology and challenges of wind energy generation: A review. Sustainable Energy Technologies and Assessments, 52, p.102239. View Article

[34] Shourangiz-Haghighi, A., Diazd, M., Zhang, Y., Li, J., Yuan, Y., Faraji, R., Ding, L. and Guerrero, J.M., 2020. Developing more efficient wind turbines: A survey of control challenges and opportunities. IEEE Industrial Electronics Magazine, 14(4), pp.53-64. View Article

[35] Adekanbi, M.L., 2021. Optimization and digitization of wind farms using internet of things: A review. International Journal of Energy Research, 45(11), pp.15832-15838. View Article

[36] Ringwood, J.V. and Simani, S., 2015. Overview of modeling and control strategies for wind turbines and wave energy devices: Comparisons and contrasts. Annual Reviews in Control, 40, pp.27-49. View Article

[37] Márquez, F.P.G., Tobias, A.M., Pérez, J.M.P. and Papaelias, M., 2012. Condition monitoring of wind turbines: Techniques and methods. Renewable energy, 46, pp.169-178. View Article

[38] Paish, O., 2002. Small hydro power: technology and current status. Renewable and sustainable energy reviews, 6(6), pp.537-556. View Article

[39] Sahraei, M.H., McCalden, D., Hughes, R. and Ricardez-Sandoval, L.A., 2014. A survey on current advanced IGCC power plant technologies, sensors, and control systems. Fuel, 137, pp.245-259. View Article

[40] Sami, I., Ullah, N., Muyeen, S.M., Techato, K., Chowdhury, M.S. and Ro, J.S., 2020. Control methods for standalone and grid-connected micro-hydro power plants with synthetic inertia frequency support: A comprehensive review. IEEE Access, 8, pp.176313-176329. View Article

[41] Khan, M.J., Iqbal, M.T. and Quaicoe, J.E., 2008. River current energy conversion systems: Progress, prospects, and challenges. Renewable and sustainable energy reviews, 12(8), pp.2177-2193. View Article

[42] Kiho S, Shiono M, Suzuki K. The power generation from tidal currents by Darrieus turbines. In: Proceedings of the World Renewable Energy Congress, vol. 2. Denver, Colorado, USA; 1996. p. 1242-5. View Article

[43] Akhter, M.Z. and Omar, F.K., 2021. Review of flow-control devices for wind-turbine performance enhancement. Energies, 14(5), p.1268. View Article

[44] Acarer, S., 2020. Peak lift-to-drag ratio enhancement of the DU12W262 airfoil by passive flow control and its impact on horizontal and vertical axis wind turbines. Energy, 201, p.117659. View Article

[45] Popescu, D., Popescu, C. and Dragomirescu, A., 2017. Flow control in Banki turbines. Energy Procedia, 136, pp.424-429. View Article

[46] Adhikari, R.C. and Wood, D.H., 2018. Computational analysis of part-load flow control for crossflow hydro-turbines. Energy for sustainable development, 45, pp.38-45. View Article

[47] Dhakal, S., Timilsina, A.B., Dhakal, R., Fuyal, D., Bajracharya, T.R., Pandit, H.P., Amatya, N. and Nakarmi, A.M., 2015. Comparison of cylindrical and conical basins with optimum position of runner: Gravitational water vortex power plant. Renewable and Sustainable Energy Reviews, 48, pp.662-669. View Article

[48] Wang, L., Cui, J., Shu, L., Jiang, D., Xiang, C., Li, L. and Zhou, P., 2022. Research on the vortex rope control techniques in draft tube of Francis turbines. Energies, 15(24), p.9280. View Article

[49] Nishi, Y. and Inagaki, T., 2017. Performance and flow field of a gravitation vortex type water turbine. International Journal of Rotating Machinery, 2017(1), p.2610508. View Article

[50] Kueh, T.C., Beh, S.L., Rilling, D. and Ooi, Y., 2014. Numerical analysis of water vortex formation for the water vortex power plant. International Journal of Innovation, Management and Technology, 5(2), p.111.

[51] Bello, S.F., Lawal, R.O., Ige, O.B. and Adebayo, S.A., 2024. Optimizing vertical axis wind turbines for urban environments: Overcoming design challenges and maximizing efficiency in low-wind conditions. GSC Advanced Research and Reviews, 21(1), pp.246-256. View Article

[52] Rashid, S.M., 2024. Employing advanced control, energy storage, and renewable technologies to enhance power system stability. Energy Reports, 11, pp.3202-3223. View Article

[53] Firoozi, A.A., Hejazi, F. and Firoozi, A.A., 2024. Advancing Wind Energy Efficiency: A Systematic Review of Aerodynamic Optimization in Wind Turbine Blade Design. Energies, 17(12), p.2919. View Article

[54] Samaei, S.R. and Ghahfarrokhi, M.A., 2023. Optimizing Coastal Hydro Turbines Integrating Artificial Intelligence for Sustainable Energy Conversion. In 2th International Conference on Creative achievements of architecture, urban planning, civil engineering and environment in the sustainable development of the Middle East.

[55] Zakir, M.N., Abasin, A.R., Irshad, A.S., Elias, S., Yona, A. and Senjyu, T., 2024. Practical Wind Turbine Selection: A Multicriterion Decision Analysis for Sustainable Energy Infrastructure. Practice Periodical on Structural Design and Construction, 29(3), p.04024028. View Article