Volume 3 - Year 2016 - Pages 92-98

DOI: 10.11159/jffhmt.2016.011

Theory and Indirect Measurements of the Drag Force Acting On a Rising Ellipsoidal Bubble

Abdullah A. Kendoush1, Kim W. Gaines2, Carrie W. White2

1Department of Nuclear Engineering Technology

2Department of Electrical & Computer Engineering Technology

akendoush@augustatech.edu, kgaines@augustatech.edu, cwcarriewild@gmail.com

Augusta Technical College

Augusta, Georgia, USA

Abstract - A series of experiments were performed to obtain the drag force and rise characteristics of oblate ellipsoidal bubbles (OEB) in tap water at room temperature. The experiment utilized a 1.219m tall Plexiglas column with square cross section of 15.24cm sides designed and constructed for this purpose. Photographs captured the bubbles as they rose and grew vertically in the water column, and were analysed to determine the bubble radius. The drag force and velocity of rise were determined indirectly. An equation (CD=2.667/Fr) was derived for the drag coefficient of the OEB where Fr is the Froude number. The experimental results validated this equation and earlier work by Reference [8]. The merit of this work is in the capability of the bubble's semi-major and semi-minor axes measurement being used to determine the drag coefficient and mean rising velocity of bubbles. Results were compared favourably with the current and published theoretical results.

Keywords: Ellipsoidal bubble, Two-phase flow, Drag coefficient, Froude number.

© Copyright 2016 Authors - This is an Open Access article published under the Creative Commons Attribution License terms Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2016-12-05

Date Accepted: 2016-10-24

Date Published: 2016-12-13

Nomenclature

: semi-major axis of the OEB

: semi-major axis of the OEB- b: semi-minor axis of the OEB

- c: semi-depth axis of the OEB

- B: buoyancy force

: drag coefficient

: drag coefficient : equivalent diameter of the OEB

: equivalent diameter of the OEB- D: drag force

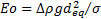

- Eo: Eötvös number (

)

)  : Froude number (

: Froude number ( for OEB) and (

for OEB) and ( for SCB)

for SCB) : acceleration due to gravity

: acceleration due to gravity- M: Morton number (

)

) - OEB: oblate ellipsoidal bubble

- Rc: basal radius of SCB

- Re: Reynolds number (Re=

U/

U/ )

)  : equivalent radius

: equivalent radius- Rsc: radius of curvature of the SCB

- SCB: spherical-cap bubble

- U: velocity of the OEB

- We: Weber number (We=2

U2/

U2/ )

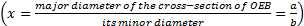

) - x: aspect ratio of the OEB

- V: volume of the OEB

: absolute

viscosity

: absolute

viscosity : kinematic

viscosity

: kinematic

viscosity : density

of liquid

: density

of liquid : surface

tension

: surface

tension

1. Introduction

There are three main stages of bubble shape development during rise in an extended liquid: spherical, ellipsoidal, and spherical-cap (SCB). The main industrial applications of bubble dynamics are found in nuclear power generation, chemical industry, oil transportation, heating, ventilation, and air conditioning, and mineral processing.

Moore

[1] analysed the motion of the OEB and obtained an equation for the variation

of the drag coefficient with respect to the aspect ratio of the OEB and

Reynolds number (Re=Udeq/![]() ) where U is the bubble

velocity, deq is the equivalent diameter, and

) where U is the bubble

velocity, deq is the equivalent diameter, and ![]() is

the kinematic viscosity of the liquid.

is

the kinematic viscosity of the liquid.

Meiron [2] solved for the distortion of the OEB from its spherical shape as the

bubble velocity increased using potential flow theory. He predicted a

functional relationship between Weber number(We=2![]() U2/

U2/![]() )

where σ is the surface tension and aspect ratio

)

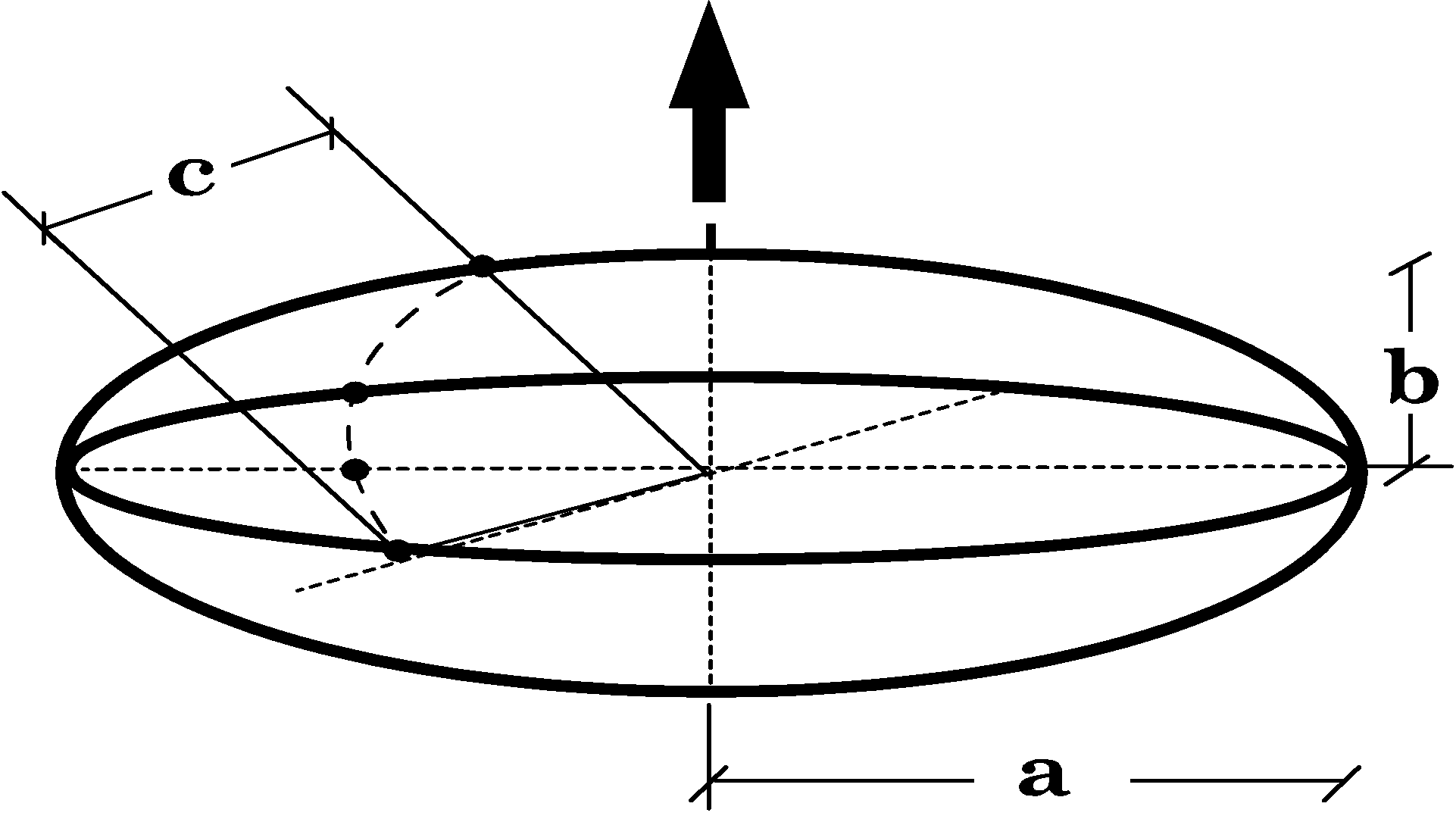

where σ is the surface tension and aspect ratio ![]() (Fig.

1).

(Fig.

1).

).

).On the experimental front, Wu and Gharib [3] concluded from their experiments that the OEB acquired a spiral path and became unstable when the bubble equivalent diameter exceeded 0.15cm or the aspect ratio exceeded 1.6. Talaia [4] performed a similar experiment to ours but used air-water system and air- glycerol system as an additional testing liquid. He acknowledged the viscosity-independence rise of a large bubble but did not make a clear distinction between the OEB and the SCB.

Wenyuan et al. [5] performed similar experiments to ours, but they used non-Newtonian aqueous solutions of polyacrylamide (PAM) and carboxymethylcellulose (CMC). Only in CMC aqueous solutions, bubbles shapes look oblate ellipsoidal similar to the ones we observed and recorded. PAM aqueous solutions produced some peculiar shaped bubbles. Aoyama et al. [6] studied the shapes of OEB's rising in infinite stagnant liquids and produced an empirical correlation for the bubble aspect ratio as a function of Eötvös and Reynolds numbers. Their definition of the aspect ratio is the reciprocal of ours. The work of Veldhuis et al.[7] revealed the existence of wakes behind the rising OEB's by using Schliern optics. They found a correspondence between these wakes and the spiraling motion of the OEB.

It appears from the literature survey that no information was provided for the experimental measurements of the drag coefficient of OEB. The main objective of this experiment was to demonstrate the possibility of measuring the dimensions of the OEB to determine its velocity and drag coefficient. In addition, some validation of previous theoretical work, by the first author, was attempted.

2. Theory

2.1. The Drag on the OEB

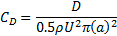

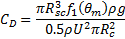

The drag coefficient of the OEB is defined as follows

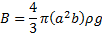

The drag force D in this equation was obtained by calculating the buoyancy force B acting on the OEB as these two forces oppose each other during the rise of the OEB under steady state conditions. Omitting the weight of the bubble, the buoyancy force B becomes

where ![]() is the density

of the liquid and

is the density

of the liquid and ![]() is the

acceleration due to gravity. Substituting this equation in Eq. (1) and B=D,

yields the following

is the

acceleration due to gravity. Substituting this equation in Eq. (1) and B=D,

yields the following

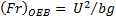

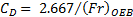

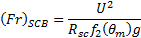

Here ![]() is the Froude number that compares the inertial

forces to the gravitational forces acting on the bubble. This equation shows

the viscous effects and the presence of surfactants do not play a significant

role on the drag particularly at high Re numbers. Ellingsen and Risso

[14] arrived at similar equation but with different parameters. This specific Fr

number was chosen to be based on the minor axis "b" because it is

considered as the main axis responsible for the symmetry of the bubble. This

specific Fr number is a more sensitive indicator of the oblateness of

the bubble, than that based on the equivalent diameter normally employed by

other authors.

is the Froude number that compares the inertial

forces to the gravitational forces acting on the bubble. This equation shows

the viscous effects and the presence of surfactants do not play a significant

role on the drag particularly at high Re numbers. Ellingsen and Risso

[14] arrived at similar equation but with different parameters. This specific Fr

number was chosen to be based on the minor axis "b" because it is

considered as the main axis responsible for the symmetry of the bubble. This

specific Fr number is a more sensitive indicator of the oblateness of

the bubble, than that based on the equivalent diameter normally employed by

other authors.

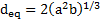

To make the

drag coefficient based on the equivalent radius, we used ![]() .

.

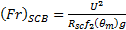

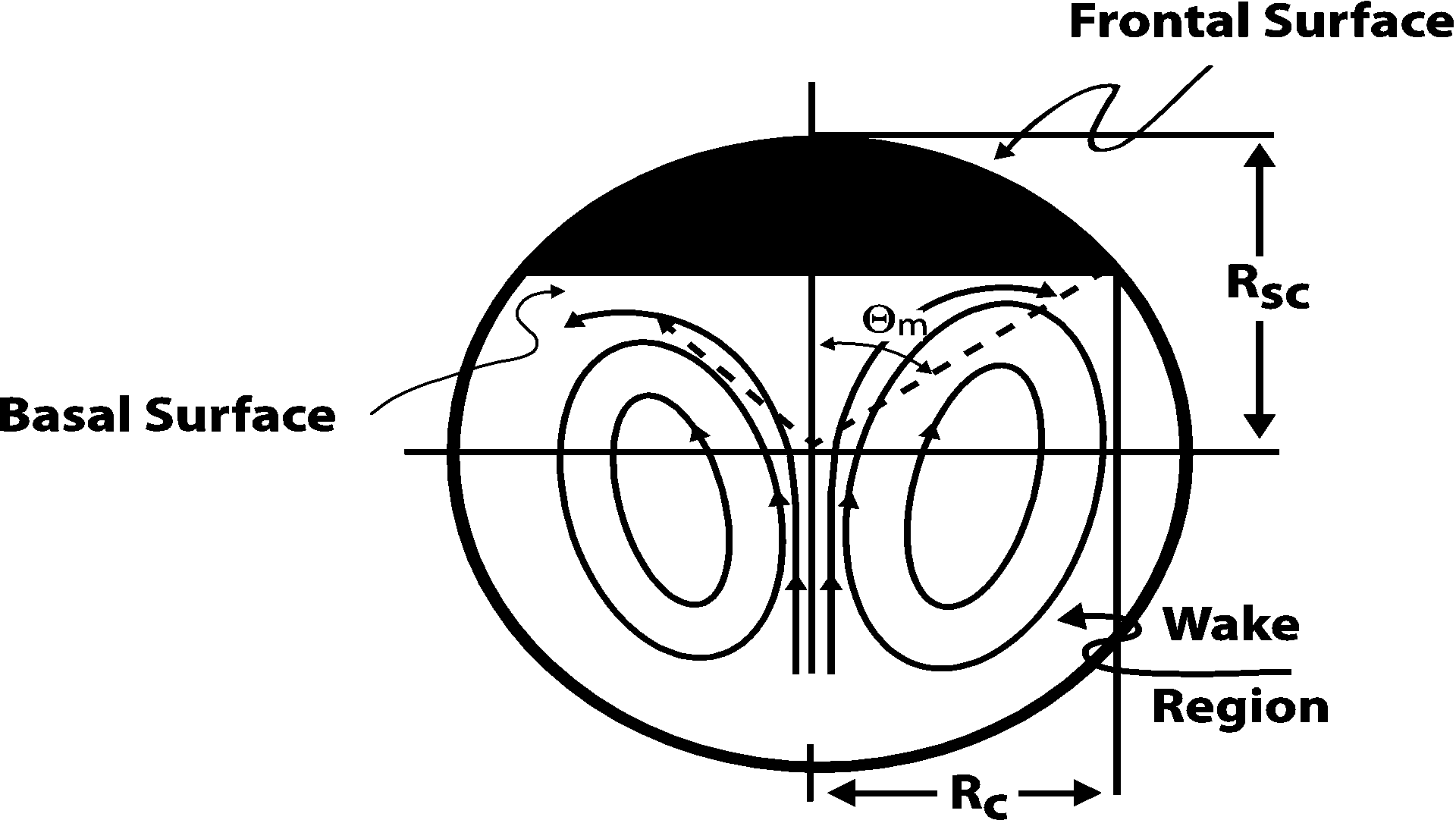

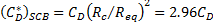

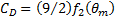

2.2. The Drag on the SCB

The following proof is to check the validity of the drag dependence on the Fr

number. We analyzed the case of the steady rise of the SCB. For Re >

100, the drag coefficient data approaches ![]() , a value obtained by many authors

(e.g., [9, 10]).

, a value obtained by many authors

(e.g., [9, 10]).

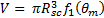

The volume of the SCB (Fig. 2) is as follows [11]

where ![]() is the wake angle, and

is the wake angle, and ![]() =

=![]() .

.

The

wake angle ![]() of the SCB lies within the range of

(45 - 56) degrees [12, 13]). Assuming that an average wake angle of 52 degrees

was considered, Eq. (4) becomes the following

of the SCB lies within the range of

(45 - 56) degrees [12, 13]). Assuming that an average wake angle of 52 degrees

was considered, Eq. (4) becomes the following

It

should be noted that the factor 0.129 in this equation has a range of 0.077-

0.166 based on the choice of ![]() with the average value of

with the average value of ![]() . The volume

of an equivalent sphere corresponding to the above volume is as follows

. The volume

of an equivalent sphere corresponding to the above volume is as follows

Equating Eq. (4) and (5) yields,

From

the idealized geometry of the SCB (Fig. 3), we have ![]()

This radius is useful in calculating the drag coefficient as it provides for the projected area as shown below

where ![]() is the drag coefficient of the SCB

based on equivalent radius, and

is the drag coefficient of the SCB

based on equivalent radius, and ![]() is the equivalent

radius of the equivalent spherical volume of the SCB. Setting the drag force

equal to buoyancy, the following is derived

is the equivalent

radius of the equivalent spherical volume of the SCB. Setting the drag force

equal to buoyancy, the following is derived

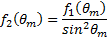

Through further simplification of this equation,

where

and

Davis and Taylor [18] found in their work that

Substituting Eq. (13) into Eq. (10) yields

As

far as the authors are aware, this new equation for the drag coefficient of the

SCB was not reported before. Further, the equation needs consideration for

future validation work. This is a powerful equation that determines the drag

from a single measurement of the wake angle. For ![]() 52 degrees, this equation becomes

52 degrees, this equation becomes

Substituting this equation into Eq. (8), yields

This is the same equation of Wegener and Parlange [9] mentioned earlier. Thus, we proved that the new Fr number-dependent drag coefficients of Eq. (3) have some kind of validity.

3. Apparatus and Procedure

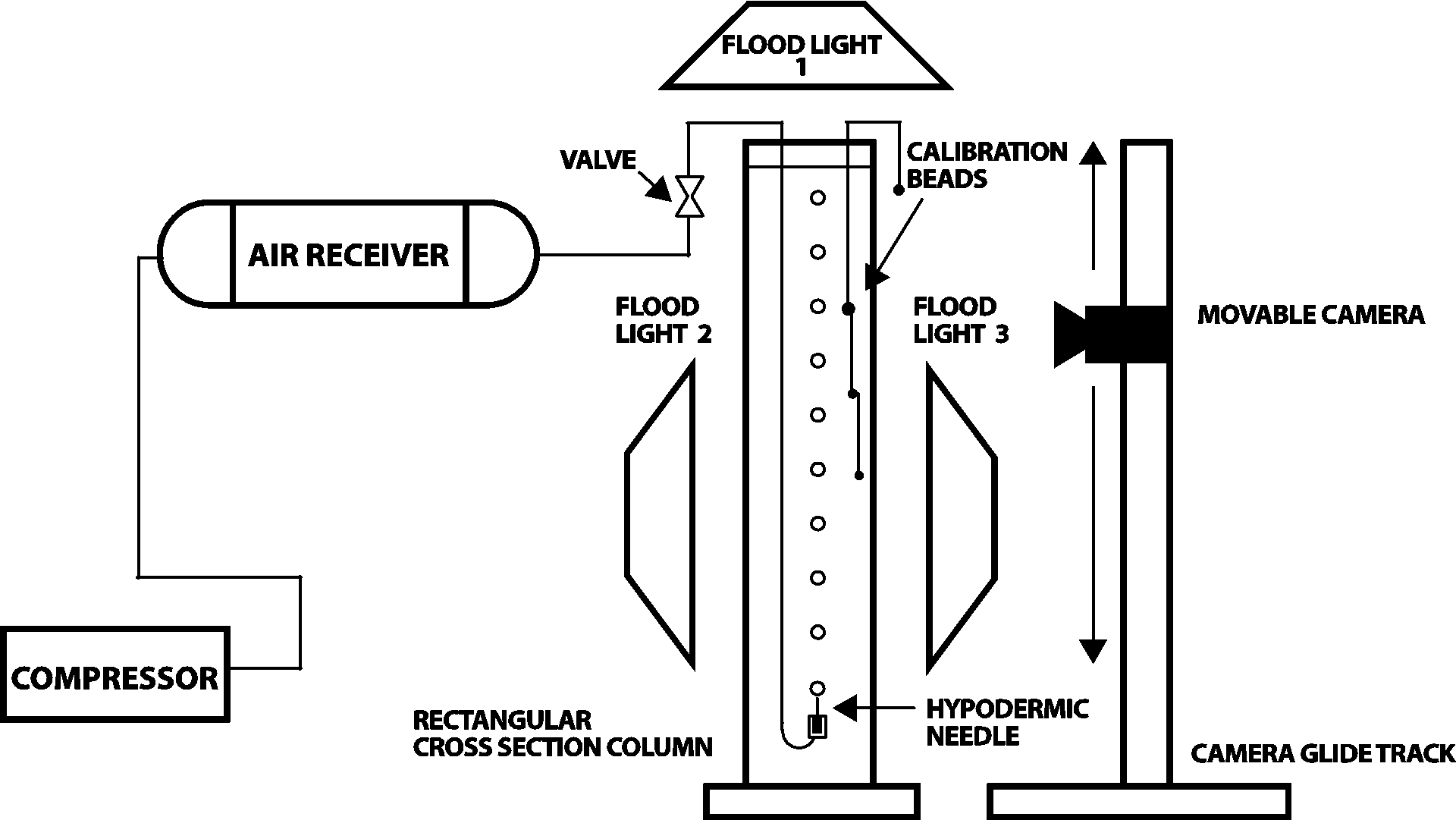

The experiments were carried out in a Plexiglas column with a 1.219m height and a cross-section of 15.2x15.2 cm (Fig. 3). The column was filled with tap water at 20 oC at atmospheric pressure.

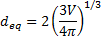

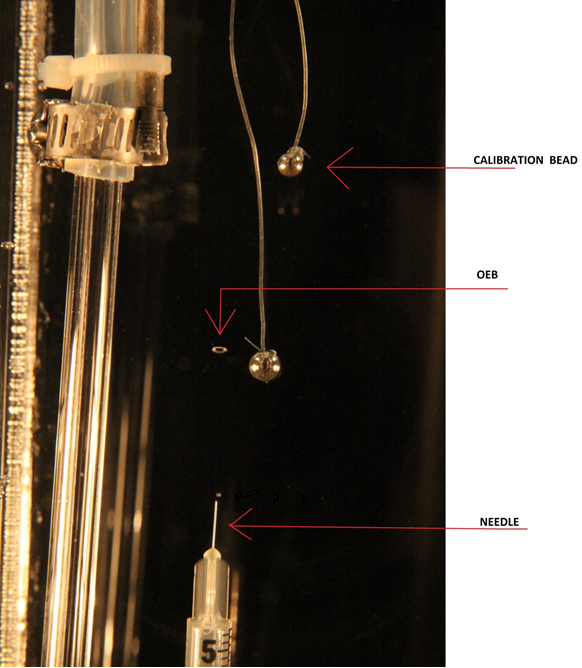

Air was introduced into the column via an air compressor, a pressure regulated air receiver, clear vinyl tubing, and a manually operated valve. The clear tube was fitted with a glass cane-shaped appendage. The cane-shaped glass ensured the bubble would rise in the middle of the tank. A 1cc syringe with an inside needle diameter of 0.1397mm was used to introduce air bubbles into the column through a hand controlled valve. Illumination for the experiment was achieved using flood lights. A Canon camera 60D, with a Tamron SP 24-70MM F/2.8 Di VC USD lens was used with an image resolution of 0.084 x 0.081 mm/pixel (5184 x 3456 effective pixel size). The camera with a 7 fps (frames/second) rate was manually moved to ensure the bubble remained in the center of the frame of reference throughout its rise. Calibration of bubble size was accomplished via three solid spherical beads with diameters of 4.978 ±0.001mm, 3.3937±0.0001mm, and 2.972±0.001mm respectively. The beads were lowered into the rectangular column with clear fishing string. The typical distance on which the bubble was filmed was (20-30cm). No attempt was made to measure the rising speed of the camera. The camera was moved manually following the rise of the OEB bubble. The following equivalent sphere diameter was used in the processing of the data

where ![]() is the volume of the OEB that is

given by

is the volume of the OEB that is

given by

and ![]() is

the semi-major axis, b is the semi-minor axis, and c is the semi

depth axis ( Fig. 1). The photographs produced a two-dimensional image with

measurable

is

the semi-major axis, b is the semi-minor axis, and c is the semi

depth axis ( Fig. 1). The photographs produced a two-dimensional image with

measurable ![]() and

b axes. The length c was assumed to be equal to the semi-major

axis; therefore, Eq. (18) becomes

and

b axes. The length c was assumed to be equal to the semi-major

axis; therefore, Eq. (18) becomes

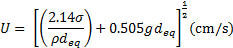

The OEB bubble velocity was not measured directly, but calculated using the following [12]

![]() in this equation was measured and

used to calculate bubble velocity. The water properties were listed in Table 1.

When the bubble detaches from the needle, its shape is spherical (

in this equation was measured and

used to calculate bubble velocity. The water properties were listed in Table 1.

When the bubble detaches from the needle, its shape is spherical (![]() =1).

As the bubble rises in the column, its shape flattens, gradually becomes OEB

and its motion becomes oscillatory.

=1).

As the bubble rises in the column, its shape flattens, gradually becomes OEB

and its motion becomes oscillatory.

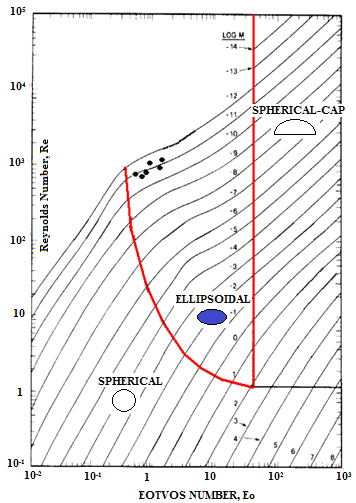

Figure

4 shows the flow regime map of the three main bubble shapes (i.e. spherical,

ellipsoidal, and spherical cap) as given by Clift et al. [12]. Based on

calculating Re number, Morton number (![]() ), and Eötvös number (

), and Eötvös number (![]() ), our experimental results fall

within the OEB region (filled dots). This region was characterized by Clift et

al. [9] as a wobbling OEB. Our results were concerned with the mean rising

motion and deformation of the bubble.

), our experimental results fall

within the OEB region (filled dots). This region was characterized by Clift et

al. [9] as a wobbling OEB. Our results were concerned with the mean rising

motion and deformation of the bubble.

Our

range of Re number was 506 - 979, M = 2.569 x ![]() , and the range of

, and the range of ![]() was 0.415 - 2.41.

was 0.415 - 2.41.

Figure 5 shows a typical photograph of the rising OEB in water with the hanging calibration beads.

Table 1. Water properties at 20 ̊C.

| Density kg/m3 | Surface Tension N/m | Kinematic viscosity m2/s |

| 998.2 | 72.74*10-3 | 1.0034*10-6 |

4. Results and Discussion

We followed the experimental evidence of Ellingsen and Risso [14] who proved the influence of surfactant of the tap water was negligible on the bubble motion. This, in addition to the derived Eq. (3), motivated us to use Eq. (20) in the present calculations of the bubble velocity, despite the fact that the equation was supposed to be applied to a clean system. The bubble emerges from the tip of the needle via a hand-regulated valve. It starts rising in spherical form, and then it changes to ellipsoidal.

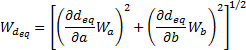

Figure

6 A, B, and C show favourable comparisons between the present experimental data

(particularly Fig. 6B and C) and the theoretical results of Kendoush [8], Moore

[1], and Blanco and Magnuadet [15]. There is a discrepancy at ![]() =1.5

of Fig. 6A between theory and experimental data. This can be attributed to

the closeness of

=1.5

of Fig. 6A between theory and experimental data. This can be attributed to

the closeness of ![]() =1.5

to bubble sphericity. Bubble motion in this region is rectilinear and Ellingsen

and Risso [14] indicated that the rectilinear trajectory is unstable. However,

Kendoush's [8] theory seems to be closer to the experimental data than both

Moore [1] and Blanco and Magnuadet [15]. It should be noted that the values of

the aspect ratio

=1.5

to bubble sphericity. Bubble motion in this region is rectilinear and Ellingsen

and Risso [14] indicated that the rectilinear trajectory is unstable. However,

Kendoush's [8] theory seems to be closer to the experimental data than both

Moore [1] and Blanco and Magnuadet [15]. It should be noted that the values of

the aspect ratio ![]() was

obtained directly from the photographs of the OEB, hence the photographs

determined the values of

was

obtained directly from the photographs of the OEB, hence the photographs

determined the values of ![]() .

.

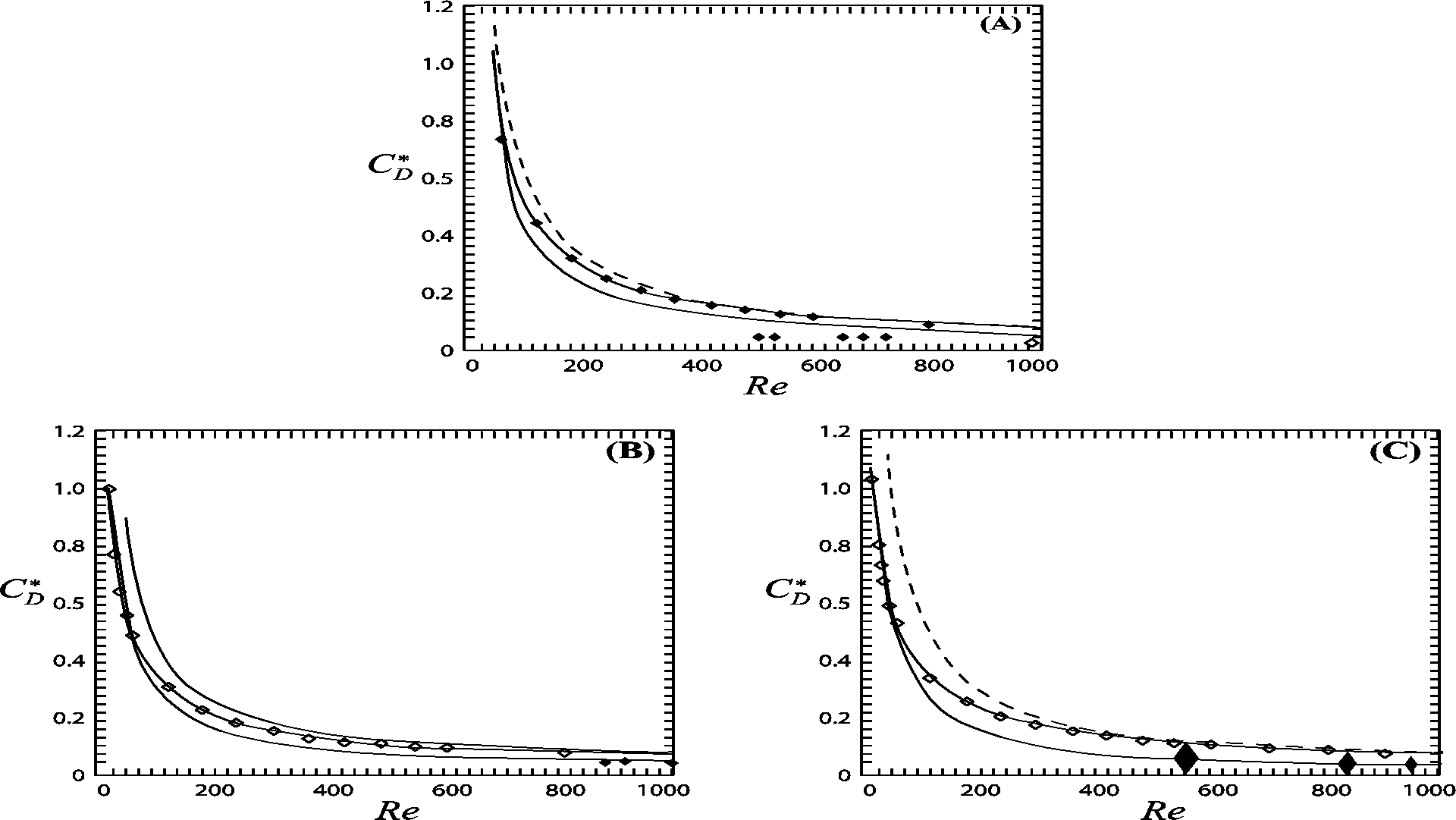

The

newly-derived Equation (3) indicates that the drag forces are independent of

viscous effects. For sufficiently high Reynolds number, the drag coefficient no

longer evolves with the Re number. Figure 7 shows a close agreement between the derived Eq. (3) and the experimental data. The

experimental data are based on the velocity of bubble rise obtained from Eq.

(20) and the measured bubble dimension b. These velocities and b

were used into ![]() to get

to get ![]() .

.

5. Uncertainty Analysis

To

find the uncertainty in the measured values of ![]() , we substitute Eq. (19) into (17) to

get the following after simplification

, we substitute Eq. (19) into (17) to

get the following after simplification

Call

the uncertainty in ![]()

![]() Uncertainty can be obtained by

applying the following equation (Holman [16])

Uncertainty can be obtained by

applying the following equation (Holman [16])

where

the uncertainty in measuring the parameter "![]() " is

" is ![]() = ± 0.01mm and the uncertainty in

measuring b is

= ± 0.01mm and the uncertainty in

measuring b is ![]() = ± 0.05 mm. Adding these errors to

those reported in §3, we get

= ± 0.05 mm. Adding these errors to

those reported in §3, we get ![]() mm and

mm and ![]() = ± 0.0952 mm. Partial

differentiating Eq. (21) and substituting in Eq. (22) yielded

= ± 0.0952 mm. Partial

differentiating Eq. (21) and substituting in Eq. (22) yielded ![]() = ± 1.665 mm or (21.16%).Suneetha

and Raghuram [17] measured the bubble diameter by using a high speed camera.

They reported 18% percentage error in their measurements. The same procedure

was done on Eq. (20) and yielded

= ± 1.665 mm or (21.16%).Suneetha

and Raghuram [17] measured the bubble diameter by using a high speed camera.

They reported 18% percentage error in their measurements. The same procedure

was done on Eq. (20) and yielded ![]() = ± 3.596 cm/s or 9.65 %. In

addition, using Eq. (3) yielded

= ± 3.596 cm/s or 9.65 %. In

addition, using Eq. (3) yielded ![]() = ± 0.0783 or 19.79 %.

= ± 0.0783 or 19.79 %.

= 1.5, (B)

= 1.5, (B)  = 1.75, and (C)

= 1.75, and (C)  = 1.95.

= 1.95.

6. Conclusion

The present work dealt with experiments on isolated air bubbles of the oblate ellipsoidal shape. Oblate ellipsoidal bubble was rising in still water. Photographs of OEB's were captured and analysed, and the data were recorded. From the photographic data, we obtained information on bubble velocity and drag. The present experimental results validated the newly-derived drag Eq. (3). This study showed that the present results also validated earlier publication of Kendoush's [8] drag equations of the OEB at high oblateness values.

Future studies will include alternate fluids, thus varied Re numbers, and aspect ratio values.

Acknowledgements

Thanks to the Southern Nuclear Company, Mr. Stephen Schroeder, Mr. J. Michael Weiksner, Sr., Dr. David M. Maryniak, and Ms. Sherrie Rowe for their efforts and support.

References

[1] D. W. Moore, "The velocity of rise of distorted gas bubbles in a liquid of small viscosity," J. Fluid Mech., vol. 23, pp. 749-766, 1965. View Article

[2] D. I. Meiron, "On the stability of gas bubbles rising in an in viscid fluid," J. Fluid Mech., vol. 198, pp. 101-114, 1998. View Article

[3] M. Wu and M. Gharib, "Experimental studies on the shape and path of small air bubbles rising in clean water," Phys. Fluids, vol. 14, pp. L49- L52, 2002. View Article

[4] M. A. R. Talaia, "Terminal velocity of a bubble rise in a liquid column," Int. J. Mathematical, Computational, and Quantum Engineering, vol. 1, pp. 214-218, 2007. View Article

[5] F. Wenyuan, M. Youguang, J. Shaokun, Y. Ke and L. Huaizhi, "An experimental investigation for bubble rising in non-Newtonian fluids and empirical correlation of drag coefficient," ASME J. Fluids Engineering, vol. 132, pp. 021305-1 - 021305-7, 2010. View Article

[6] S. Aoyama, K. Hayashi, S. Hosokawa and A. Tomiyama, "Shapes of ellipsoidal bubbles in infinite stagnant liquids," Int. J. Multiphase Flow, vol. 79, pp. 23-30, 2016. View Article

[7] C. Veldhuis, A. Biesheuvel and L. Van Wijngaarden, "Shape oscillations on bubbles rising in clean and tap water," Phys. Fluid, vol. 20, p. 040705, 2008. View Article

[8] A. A. Kendoush, "Heat, mass, and momentum transfer to a rising ellipsoidal bubble," Ind. Eng. Chem. Res., vol. 46, pp. 9232-9237, 2007. View Article

[9] P. P. Weneger and J.-Y. Parlange, "Spherical-cap bubble," An. Rev. Fluid Mech., vol. 5, pp. 79- 100, 1973. View Article

[10] D. D. Joseph, "Rise velocity of a spherical-cap bubble," J. Fluid Mech., vol. 488, pp. 213-223, 2003. View Article

[11] A. A. Kendoush, "Theory of convective heat and mass transfer to spherical-cap bubbles," AIChE Journal, vol. 40, pp. 1440-1448, 1994. View Article

[12] R. Clift, J. R. Grace and M. E. Weber, Bubbles, drops, and Particles, New York: Academic Press, 1978. View Book

[13] J. R. Landel, C. Cossu and C. P. Caulfield, "Spherical-cap bubbles with a toroidal bubbly wake," Phys. Fluids, vol. 20, no. 12, pp. 122101-1-122101-3, 2008. View Article

[14] K. Ellingsen and F. Risso, "On the rise of an ellipsoidal bubble in water: oscillatory paths and liquid-induced velocity," J. Fluid Mech., vol. 440, pp. 235-249, 2001. View Article

[15] A. Blanco and J. Magnuadet, "The structure of the axisymmetric high-Reynolds number flow around an ellipsoidal bubble of fixed shape," Phys. Fluids, vol. 7, no. 6, pp. 1265-1274, 1995. View Article

[16] J. P. Holman, Experimental Methods for Engineers, New York: McGraw-Hill, Inc., 1989. View Book

[17] T. B. Suneetha and P. T. Raghuram, "Bubble size measurements and error analysis in a gas-liquid ejector," Indian J. Chemical Technology, vol. 19, pp. 442-446, 2012. View Article

[18] R. M. Davies and S. G. I. Taylor, "The mechanics of large bubbles rising through extended liquids in tubes," in Proc. Roy. Soc., London, 1950. View Article